THE MOST EXCLUSIVE AND BESPOKE BENTLEY OF THE MODERN ERA

The £1.8 million Bacalar has been crafted using the Barchetta’ design principles to deliver the ultimate expression of open-top, driver-focused grand touring. Just 12 of these distinctive masterpieces will be designed, engineered and handcrafted by the expert craftspeople within the oldest coachbuilding company in the world – Bentley Mulliner.

The rarest two-door Bentley of the modern era, and the ultimate expression of two-seat, open-air luxury. This definitive Grand Tourer spearheads a return to the ultimate in exclusivity with each being tailored to, pre-allocated, customers’ tastes – marking a return to bespoke coachbuilding.

This exceptionally rare car becomes a statement of purpose for the future. The Bacalar now propels Bentley into a new century of extraordinary, as the design team has envisaged the most dynamically sculpted model to date. The dramatic, tapered cowls at the rear hark back to the Barchetta sports cars of old, whilst underlining the promise of a dynamic, driver-focussed adventure in a cosseting, cocooned environment.

Sustainable, ethically-sourced materials previewed in the EXP 100 GT concept car have now become reality in the Bacalar. These include paint containing ash from rice husks, which provides a sustainable way of delivering a rich metallic finish, natural British wool and 5,000-year-old Riverwood sourced from the ancient Fenlands of East Anglia.

The Bacalar features an enhanced version of Bentley’s peerless 6.0-litre, W12 TSI engine. The most advanced 12-cylinder engine in the world, it produces 659 PS (650 bhp) and 900 Nm (667 lb.ft) of torque. Whilst an advanced Active All-Wheel-Drive System varies the torque split between front and rear wheels. It allows the Bacalar to use rear-wheel drive as much as possible during normal driving for optimum efficiency and dynamic performance. The drivetrain is at the heart of the Bacalar, creating the ultimate open-air, two-seat luxury Grand Tourer available in the world today

BENTLEY MULLINER BACALAR CRAFTSMANSHIP NEARS COMPLETION

- Handcrafted Bacalars near end of production

- Eight cars now handed-over to customers around the world

- Last four cars in final preparation by hand ready for delivery

- Array of bespoke specifications shows diversity of customer requests

- All cars created in Bentley Mulliner’s dedicated workshop in Crewe

- Detailed spec of one Bacalar shows depth of customisation

- Mulliner looks to the future for next bespoke model

(Crewe, 03 August 2022) Bentley Mulliner is completing the final stages of handcraftsmanship of 12 of the rarest Bentleys of the modern era – the exquisite Bacalar. The Bacalar is the ultimate expression of two-seat, open-air luxury and was the first in a new series of pinnacle bespoke projects that have spearheaded a return to coachbuilding by Bentley Mulliner – the oldest coachbuilder in the world. The imminent completion of the Bacalars will allow the Mulliner team to focus attention towards their next project, which will be revealed soon.

Eight Bacalars – each in a unique colour designed by its customer – have now been handed to their owners around the world, with the final four cars in the last phases of preparation in Mulliner’s Crewe workshop for transport and delivery. With each car taking around six months to complete, the last tasks and quality checks mark the end of a long and incredibly detailed process to craft each Bacalar according to its owner’s wishes.

Bacalar has been brought to life by Bentley Mulliner to revive its specialism in providing rare coachbuilt cars to only a few discerning customers. A roofless Barchetta design with all-new and highly muscular coachwork, embracing a myriad of options and materials, each Bacalar is truly unique, the result of direct interaction between the Bentley Mulliner design team and each individual customer. As with every car in the series, strictly limited to 12 examples, all cars have had every detail specified by their owners, and as such are totally bespoke to them.

Each carbon fibre body is finished in a bespoke colour for each individual customer with no two cars being the same. The cars sit on unique 22” Tri-Finish wheels, with polished faces, dark grey satin spokes and accent highlights to complement the exterior.

Maria Mulder, Head of Colour, Materials and Finishes, comments;

‘Designing a Bacalar is an exercise in imagination, with the material, colour and finish of practically every interior and exterior surface being bespoke. Regardless of your personal style, whether it be to specifying your Bacalar with a bold Yellow Flame exterior paint synthesised with rice husk ash, or a more subtle Moss Green that reflects Bentley’s heritage, developing your own artisan piping, or co-create a unique fabric blend, the Bacalar has provided all of these opportunities.’

Uniquely designed details and features in the cabin emphasise the coachbuilt character of the car, with an almost infinite number of ways for the 12 customers to express their personal taste and commission a unique interior.

Sustainable, ethically-sourced materials previewed in the EXP 100 GT concept car have now become reality in a number of the Bacalars. These include paint containing ash from rice husks, which provides a sustainable way of delivering a rich metallic finish, natural British wool and 5,000-year-old Riverwood sourced from the ancient Fenlands of East Anglia.

From the use of precious inlays and unique finishes to the driver controls, to the 148,199 individual stitches needed to embroider the unique Bacalar quilt on each seat, owners will find details and components not seen before on a Bentley.

Due to the nature of these personal commissions, Bentley is not able to reveal the identity of the customers nor where the cars will be heading. However, each customer shares a love of driving, along with an avid appreciation for craftsmanship, authenticity & attention to detail, all deeply associated with Mulliner.

A Perfect Example

One of the finished Bacalars took pride of place on Bentley’s show stand at this year’s Goodwood Festival of Speed, during which time it was handed over to its new owner by Bentley’s Chairman and Chief Executive, Adrian Hallmark. The specification of the car is a perfect example of how every detail of a Bacalar was chosen by its customer.

This Bacalar was finished in bespoke Sunset Orange, with customised tri-colour 22” wheels in dark grey satin with polished faces and gloss black highlights providing a bold contrast to the vibrant exterior. The centres of the headlamps were colour matched to the Sunset Orange bodywork, either side of a set of gloss black grilles and surrounds. The bonnet vents provided a textural difference being finished in satin carbon fibre, as were the wing mirrors. Satin carbon fibre also gave additional definition to the ‘power humps’ behind the front seats – accented with Sunset Orange brightware – along with the side skirts and rear diffuser, complemented by exhaust finishers with gloss black outers and matte black inners.

Side vents and the rest of the exterior brightware are in gloss black, as are the insides of the exterior door handles.

A white and black cabin with Mandarin Orange accents creates a striking contemporary interior theme. A satin carbon fibre technical finish encapsulates the occupants, sweeping from one side of the cabin to the other, matching the exterior technical details harmoniously. Every panel and detail of the interior was specified to the customer’s choice, through careful combinations of leather and Alcantara in white, black and orange, gloss and satin metals in black, dark tint and bright chrome finishes, and the twin usage of both gloss and satin carbon fibre.

Mandarin Orange leather accentuates the form of the top roll, the centre line in the steering wheel and both the door release and gear lever. This continues with further stitching details to the rear of the seats within the oval perforated Beluga piping and hand cross stitching along the door following the styling line around to the centre console.

The Bacalar is the extreme example of how the tiniest of details included in every Bentley can accumulate to form a cabin unlike any other. This customer’s car is no exception, and details include:

- The analogue clock faces of the Bentley Rotating Display provide a splash of contrast in Bacalar Blue.

- The carpets feature a ‘diamond carved’ pattern, with binding and stitching in Mandarin Orange.

- The split line between satin carbon fibre and gloss black in the luggage area – usually unseen and hidden by luggage – was specified to be in satin dark tint

- The bespoke luggage that fits behind the seats feature Alcantara uppers to match the car, along with embroidery in Mandarin Orange and oval-perforated beluga piping with a Mandarin Orange core – exactly replicating the finish to the back of the fronts seats

Infinite Choice

The specification of every Bentley is a voyage of discovery, with even a ‘standard’ model being configurable in literally billions of ways. The process of designing a Mulliner goes even further – with infinite combinations of materials, colours and finishes. The exquisite grand tourers that result are only bounded by the law of the land and the imagination of the customer. The next coachbuilt model from Mulliner – to be revealed soon – will be no exception.

BACALAR SPEARHEADS BENTLEY MULLINER’S RETURN TO THE PINNACLE OF COACHBUILDING

- Most exclusive and bespoke Bentley of the modern era revealed at Bentley’s headquarters in Crewe, England

- Two-seat Bacalar marks return to bespoke coachbuilding for Bentley Mulliner – the oldest coachbuilding company in the world

- Bentley Mulliner announces new three-portfolio future: Classic, Collections and Coachbuilt

- ‘Barchetta’ design delivers the ultimate expression of open-top, driver-focused grand touring

- Enhanced 6.0-litre W12 TSI engine produces 659 PS (650 bhp)

- Just 12 distinctive cars to be designed, engineered and handcrafted to individual customers’ tastes – all already allocated

- Design DNA and sustainable materials inspired by the EXP 100 GT concept car, launched last summer to celebrate Bentley’s centenary

- Sustainable craftsmanship and ethically-sourced materials includes rice husk ash paint and 5,000-year-old Riverwood

- Bacalar to be produced in world’s first certified carbon neutral factory for luxury car production

- Ultra-modern design includes extreme wrap-around cockpit and semi-enclosed rear compartment for bespoke Schedoni luggage

(Crewe, 3 March 2020) Bentley Mulliner has revealed the all-new Bacalar at the home of Bentley in Crewe, England this morning. The rarest two-door Bentley of the modern era, and the ultimate expression of two-seat, open-air luxury, this definitive Grand Tourer spearheads a return to coachbuilding by Bentley Mulliner – the oldest coachbuilder in the world.

Just 12 examples of this striking, limited edition model are being created, guaranteeing rarity and exclusivity, and offering supreme luxury and breath-taking performance. Bacalar looks to the future of bespoke luxury motoring – each model will be handcrafted in Bentley Mulliner’s workshop in Crewe, according to the individual customer’s personal tastes.

This exceptionally rare car is appropriately named after Laguna Bacalar in Mexico’s Yucatan peninsula, a lake renowned for its breath-taking natural beauty, continuing Bentley’s strategy of naming cars after remarkable landmarks which started with Bentayga in 2015.

Bacalar has been brought to life by Bentley Mulliner, reviving its specialism in providing rare coach-built cars to only a few discerning customers. A roofless Barchetta design with all-new and highly muscular coachwork, embracing a myriad of options and materials, each Bacalar will be truly unique, the result of direct interaction between the Bentley Mulliner design team and the individual customer.

The most exclusive two-door Bentley of the modern era launches a new Bentley Mulliner operation, and forms part of a new strategy for the world’s oldest coachbuilder that will see the division offer three different portfolios: Classic, Collections and Coachbuilt.

Bentley Mulliner has an illustrious history and can proudly trace its roots back to the 1500s when the company’s original focus was customising luxurious, horse-drawn carriages. The remarkable Bacalar is therefore the culmination of almost 500 years of expertise and heritage in the art of vehicle design.

Adrian Hallmark, Chairman and Chief Executive of Bentley Motors, comments:

“The Bentley Bacalar is our ultimate expression of an open-top, luxury grand tourer, and of the immense capabilities of our team in Crewe.

“In Bacalar, we have created a fully bespoke Bentley, orientated towards a two seat open top experience, and carrying a number of the forward thinking elements of future luxury, first heralded in our EXP100GT as part of our Centenary celebrations last year.

“Bacalar is a rare and remarkable Bentley, and whilst clearly defined, will be an extraordinary and collaborative experience for just twelve discerning people who will now co-create, collect, drive and treasure one of twelve being built.

“Our customers are as excited as we are about Bacalar, as it brings our team and discerning enthusiasts together, to create the finest bespoke, hand-built cars, and push the boundaries of our imagination and capabilities.”

A masterpiece of craftsmanship, the Bacalar is a seamless fusion of materials with an intelligent curation of technology. It draws on design DNA from the beautifully sculpted, award-winning EXP 100 GT which was recently crowned ‘Most Beautiful Concept Car of the Year’ at the prestigious French Festival Automobile International and ‘Concept Car of the Year’ by GQ magazine.

A statement of purpose for the future, Bacalar now propels Bentley into a new century of extraordinary, as the design team has envisaged the most dynamically sculpted model to date. The dramatic, tapered cowls at the rear hark back to the Barchetta sports cars of old, whilst underlining the promise of a dynamic, driver-focussed adventure in a cosseting, cocooned environment.

Pure in line and execution, the distinctive, wraparound cockpit flows from a new, steeply angled centre console seamlessly into the dashboard and doors. These then wrap rearwards towards the semi-enclosed luggage compartment behind the two seats.

Sustainable, ethically-sourced materials previewed in the EXP 100 GT concept car last year have now become reality in the Bacalar – just eight months after first being previewed. These include paint containing ash from rice husks, which provides a sustainable way of delivering a rich metallic finish, natural British wool and 5,000-year-old Riverwood sourced from the ancient Fenlands of East Anglia.

The Bacalar features an enhanced version of Bentley’s peerless 6.0-litre, W12 TSI engine. The most advanced 12-cylinder engine in the world, it produces 659 PS (650 bhp) and 900 Nm (667 lb.ft) of torque.

An advanced Active All-Wheel-Drive System varies the torque split between front and rear wheels. It allows the Bacalar to use rear-wheel drive as much as possible during normal driving for optimum efficiency and dynamic performance. The drivetrain is at the heart of the Bacalar, creating the ultimate open-air, two-seat luxury Grand Tourer available in the world today.

All examples of the exquisite Bentley Mulliner Bacalar have already been allocated to customers from around the world.

Bentley Mulliner Returns To Coachbuilding

With the Bacalar, customers will again have the ability to work closely with a team of specialist designers to enhance their vehicle with a selection of unique materials and specially curated options. The Bacalar will be the first – but other new bespoke Bentleys will follow as part of the Bentley Mulliner Coachbuilt portfolio – one of three new divisions of the Bentley Mulliner organisation.

The Bentley Mulliner Classic offering was introduced last year with the announcement that Bentley’s 1929 Team Blower is to be reborn with a new build of 12 supercharged 4½-litre examples of the iconic car. These models, each individually handcrafted by a team of specialists from Bentley Mulliner, will form the world’s first pre-war race car continuation series. This subdivision of Mulliner also completed an immaculate restoration of the 1939 Bentley Corniche last year.

The third arm of the business – Bentley Mulliner Collections – will continue to offer customers luxury-focused derivatives of the core Bentley range, such as the new Continental GT Mulliner Convertible, as well as the opportunity to personalise their new Bentley. An expansive number of options is available across the full line-up of current production cars – from unique colour-matched paint, hide and thread combinations, to bespoke feature content.

Tracy Crump, Bentley Mulliner’s Head of Commercial Operations, comments:

“While Bentley’s motto is ‘Be Extraordinary’, at Bentley Mulliner we look to take it one step further, ‘Beyond Extraordinary’. With the new Bacalar we have been able to do exactly that, providing a select number of customers with the opportunity to express their personal taste in a truly remarkable grand tourer. Meanwhile, Bentley Mulliner Classic will breathe new life into the most iconic cars from our past, while our Collections team continue their work to offer a bespoking service to each and every Bentley customer.”

Bacalar – A Dynamically-Sculpted Design For The Future

The new Bentley Bacalar is a genuine ‘roofless’ Barchetta – a luxury, two-seat, open-air performance car, the likes of which has never been seen before. Handcrafted to the individual customer’s personal tastes, Bacalar is the ultimate expression of an open-top Grand Tourer: a spirited GT combining traditional handcrafted techniques with the latest cutting-edge technology.

The Bacalar shares no body panel with any other car in the Bentley model line-up and derives inspiration from the dramatic EXP 100 GT concept car conceived to mark the company’s centenary last year. Indeed, it only shares one exterior component with a Continental GT – the door handle, simply because it contains the keyless entry system.

Stefan Sielaff, Bentley’s Director of Design, comments:

“You can clearly see echoes of the EXP 100 GT in the Bacalar, as well as the influence of the past. Bentley has a rich history of open-cockpit cars – the design of the Birkin Blower Bentley of the late 1920s was also an inspiration. We needed to push the boundaries as far as possible – customers were asking what Bentley’s take on a more expressive-looking car at this price point would look like. We were also tasked with starting to deliver on Bentley’s promise to use sustainable materials. Within less than a year of revealing our future-focused concept, we have already delivered on this promise.”

The rear clamshell and top deck of the Bacalar are crafted from lightweight aluminium, while the doors and wings are carbon fibre. Combined with the use of three-dimensional printing, it has allowed designers to create an even more distinctive car.

The Bacalar sits on extended haunches, with the rear track 20 mm wider than a Continental GT, to provide a more muscular, sporting stance. They house bespoke, 22-inch tri-finish wheels with dramatic depth and contour on the road. The unique front and rear horizontal lights add the distinctive, dynamic character that was first seen on the EXP 100 GT.

Instead of a traditional badge, Bentley designers went the extra mile to find a special way to identify the car. Uniquely, the Bacalar name appears on the rear panel, ‘hidden’ behind the lacquer of sustainable rice husk paint, with the capital ‘A’s influencing the contours of the lower bumper area.

The exterior look of each model will be completed in collaboration with individual customers, who are able to further personalise their car, choosing from rare paint options, exterior treatments and design themes. The Bacalar represents a return to the exciting early years of Bentley, allowing owners to help shape the car of their dreams.

A Unique Wraparound Cockpit

Inside the luxurious cabin, Bentley craftspeople have created a cockpit like no other. The architecture of the Bacalar has allowed Bentley Mulliner designers to seize the opportunity to create a theme that not only blends the interior and exterior together but also emphasises the two-seater character with a ‘wraparound’ cockpit design.

Pure in line and surface execution, the wraparound design flows from a steeply angled centre console into the dashboard, before sweeping into the door panels. These then wrap towards a uniquely styled, semi-enclosed luggage compartment behind the seats.

This ingenious space is purposely designed for bespoke Schedoni fitted luggage, the Italian company that has designed luxury luggage for the automotive industry for almost 140 years. Created exclusively for the Bacalar, the optional luggage perfectly matches the trim and materials of the cabin. These two luggage ‘pods’ flow from the interior into the exterior, enveloping the seats and creating a true two-seater cabin.

Uniquely designed details and features in the cabin emphasise the coach-built character of the car, with an almost infinite number of ways for customers to express their personal taste and commission a unique interior.

Every detail has been uniquely designed. A new, knurled pattern was created for the iconic ‘bullseye’ vents – a pattern that was repeated around the interior on areas like the steering wheel controls, media and climate controls and even the intricate speaker frets. Each element has a fine, Dark Bronze detail to further enhance the finish, with Midnight Black Titanium detailing.

The dark, anodised titanium finish on the main controls and a metallic dark bronze on the iconic Bulls-eye air vents have been used to highlight further details.

The interior can be finished in any number of ways, with each car co-created and commissioned in conjunction with the Bentley Mulliner team. Every car will be individually specified and finished using any of the many Bentley colours and materials available.

The finest Beluga leather is carefully sewn together with Bentley’s heritage semi-gloss leather and natural wool to create a dark ‘tone-on-tone’ character. For the first demonstration car, the use of Bentley Mulliner’s Khamun accent leather highlights the wraparound cabin theme and matches the new and unique Yellow Flame exterior paintwork perfectly.

Every element that falls to hand has been specifically designed for the Bacalar. A new D-shaped steering wheel features Alcantara inserts, with a contrast accent top marker. The gear-shifter is also finished in Alcantara with Dark Bronze detailing. Unique leather strap door and seat releases, unique digital instrumentation and a unique key design enhance the luxurious cabin still further.

At the heart of the centre console is the now famous Bentley Rotating Display. This digital MMI display has been elegantly designed by Bentley with a customer-configurable home screen. The system involves 40 moving parts and revolves the Riverwood veneer when the engine is started to reveal the high-resolution touchscreen.

Three configurable windows are able to display the driver’s preferred functions, such as telephone, media and navigation. The interface is designed to operate like a modern smartphone, with menus that are structured and simple to follow. The third side of the Bentley Rotating Display presents three, elegant analogue dials that display outside temperature, a compass and chronometer – providing an alternative to the touchscreen when the driver wants to digitally detox.

Each car also features a unique clock face with individual one-of-12 badging.

Owning a Bacalar is the start of a journey of discovery for the owner. Every element has been carefully and meticulously designed with a depth so great that over the course of time, each customer will discover new and interesting details.

From the use of precious inlays and unique finishes to the driver controls, to the 148,199 individual stitches needed to embroider the unique Bacalar quilt on each seat, owners will find details and parts not seen before on a Bentley.

Sustainable Craftsmanship And Ethically-Sourced Materials

Bentley has entered into collaborative relationships with carefully selected industry experts to create the new Bacalar. Each one uses sustainable and innovative techniques that exemplify the best craftsmanship that the world has to offer, in many cases fine-tuned over centuries, and using ethically-sourced materials.

A focal point of the cabin is the wraparound dashboard cut from rare Riverwood, a sustainable wood from naturally fallen trees that has been preserved for 5,000 years in peat bogs, lakes and rivers found in the Fenlands of East Anglia, England.

This exquisite wood was chosen for its striking black aesthetic, the result of lying untouched in wet earth for thousands of years. The wood has been air-dried in a controlled environment over a long period of time to prevent damage and conserve its unique, natural characteristics. The straight grain enhances the Bacalar’s sweeping interior contours, giving it genuine soul and drama.

Once veneered, the dashboard is literally sliced in two, creating an upper and lower element divided by a 3mm chrome strip. The upper Riverwood is finished as open pore – a semi-matt finish that shows off the veneer’s grain and colour.

The lower panels are a high gloss finish but with a modern twist to the traditional process. The Bacalar’s lower dashboard blends seamlessly from veneer into a high gloss piano black, further underlining the unique and bespoke finishes that are available. Because the Bacalar has no roof, this stunning marquetry is clearly visible from outside the car.

Bentley Mulliner has also collaborated with a traditional British textile mill to produce bespoke natural wool cloth akin to a fine tailor’s suit. Bentley Mulliner has embraced the expertise and knowledge of these centuries-old methods to create an exclusive and unique woven cloth especially for the Bacalar, and customers will have the option to co-create their own bespoke fabric blend.

This traditionally-produced textile is used in the seat inserts, seat backs and the side of the head restraints. Following the interior styling lines, it also flows from the side of the centre console and lower instrument panel into the doors.

Further promoting sustainable craftsmanship and supporting a unique industry, the luxury overmats are precision woven on traditional Wilton looms in England using the finest natural yarns. These Wilton-woven pure wool deep pile carpets are hand-carved for the footwell and rear luggage compartment, following the embroidered pattern found on the seats.

Thanks to a partnership with another local supplier, based in the nearby Peak District, the Bacalar also offers customers the rare opportunity to create individual artisan piping, chosen to enhance the dynamic styling lines of the seat architecture. This piping can be designed and customised to feature unique patterns, colour combinations and personal embossed effects, such as a customer’s signature or special, individual customer motifs.

Even the paintwork on the Bacalar has been specially chosen for its sustainable characteristics. The pigment reflects an eye-catching transition of colour that intensifies the drama, form and contours of the sculpted exterior in different lights.

The pigment is synthetically-manufactured silicon dioxide platelet coated with iron oxide. This synthetic process uses rice husk ash – a by-product from the rice industry – to create 90 per cent pure silicon dioxide, thereby reducing rice husk landfill waste.

Each Bacalar will be hand-crafted in Mulliner’s dedicated workshop at the Bentley factory in Crewe – the world’s first certified carbon neutral factory for luxury car production.

A Unique Driving Experience

The Bentley Bacalar combines bespoke, hand-crafted luxury with state-of-the-art technology to guarantee an extraordinary driving experience.

With all-new coachwork brought to life by Bentley Mulliner, at the heart of the Bacalar is Bentley’s renowned 6.0-litre, twin-turbocharged W12 TSI engine mated to a technically-advanced drivetrain.

The Bacalar’s dual-clutch, eight-speed transmission offers faster, more efficient gear changes. An adaptive chassis uses Bentley’s intelligent, 48-volt Dynamic Ride System to ensure a responsive ride and exceptional handling and refinement in all conditions.

The air suspension system controls ride comfort and lateral roll, cushioning passengers from excessive movement, as well as making the Bacalar feel effortlessly precise.

The Legend Of Mulliner

The legend of Mulliner is woven into the very fabric of Bentley. The tradition of bespoke craftsmanship has been passed down from generation to generation since the 1500s, when Mulliner was founded as a saddler.

In the 1760s, the Mulliner family business refocused on coachbuilding and rose to prominence when it was commissioned to build and maintain carriages for the Royal Mail postal service. With the arrival of the motor car, the company stepped away from horse-drawn carriages and focussed on coachbuilding for mechanical propulsion.

The then independent Mulliner crafted a bespoke, 3-litre, two-seater Bentley for the 1923 Olympia Show in London, creating a bond between the two companies that would last for decades. Mulliner bodied over 240 Bentley chassis in the 1920s alone and became renowned as the very best of the new coachbuilding firms.

Perhaps the most famous was Mulliner’s design for the 1952 R-Type Continental, still considered one of the most beautiful cars of all time. The fastest, four-seat sports car of the era, the R-Type’s iconic beauty continues to influence design today through the Bentley Continental GT.

Mulliner cemented its partnership with Bentley in 1959 by becoming part of the business. It later moved into the old engineering experimental department at Bentley headquarters in Crewe and has remained there ever since. Today, around 40 employees, ranging from specialists with over 40 years of Mulliner experience to apprentices learning the skills that have been honed over decades of manufacturing, work for the company.

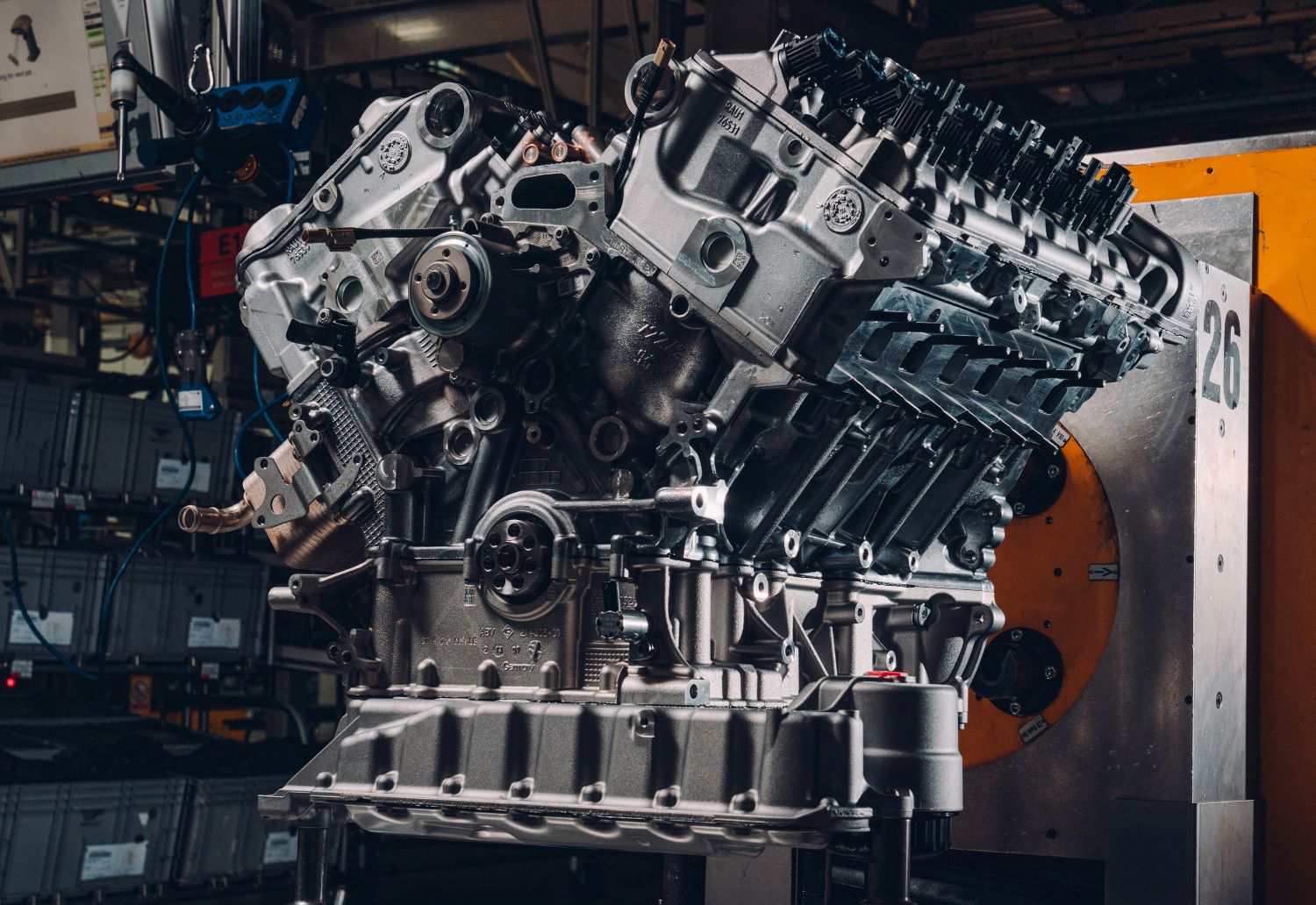

BACALAR W12 ENGINE COMPLETES TESTING

- First W12 engine destined for Bacalar completes production testing at Bentley’s centre of excellence for W12 engines

- Bentley’s W12 is the most advanced 12-cylinder engine in history

- Producing 659 PS (650 bhp) and 900 Nm (667 lb.ft) of torque

- W12 engine development has increased power by up to 27 per cent, torque by 38 per cent and reduced emissions by 28 per cent since 2003

- Each engine passes through three specific test regimes before fitting to a vehicle

- More than 100,000 W12 engines have been handbuilt at Crewe since 2002, producing more than six million horsepower