Gordon Murray Automotive T.50: Global premiere

- Engineered to be the most driver-centric supercar ever built

- Full exterior and interior revealed showing design purity and fastidious attention to detail

- 3.9-litre V12 is the world’s lightest, highest-revving, most power dense naturally-aspirated road car engine

- 986kg total vehicle weight is lighter than the typical supercar by almost a third

- Most advanced and effective aerodynamics ever seen on a road car, enabled by Murray’s unique rear-mounted fan

- Far from a track-focused tool, T.50 offers day-to-day usability, practicality refinement and comfort alongside its ferocious performance

- Limited to production run of just 100

4 August 2020 – Gordon Murray Automotive has unveiled its T.50 supercar in full for the first time, showing the finished exterior and interior design and confirming its ground-breaking technical specifications. The T.50 has been engineered to be the purest, lightest, most driver-centric supercar ever.

Improving on his acclaimed McLaren F1 “in every conceivable way”, Professor Gordon Murray CBE is leading the team that will begin building customer versions of the 986kg supercar in January 2022. Justifying its £2.36m (before taxes) price tag, the T.50 promises to deliver an unsurpassed driving experience. It is powered by a 100% bespoke 3.9-litre, 663PS V12 engine that revs to a record-breaking 12,100rpm, and features the most advanced and effective aerodynamics ever seen on a road car – aided by a 400mm rear-mounted fan.

The global premiere is the first time the clean lines of the exterior and the driver-focused interior have been seen. From his first ballpoint sketches, to every engineering and design detail, Murray has led the Gordon Murray Automotive team and briefed and overseen suppliers to drive the project forward at an unrelenting pace. Murray’s design for T.50 was the 50th in a prestigious line of race and road cars he’s penned over his illustrious 50-year career – both reasons combining to name the car T.50.

The most dominant characteristics of the T.50 exterior design are its purity and balance, free from the wings, skirts and vents that adorn most modern-day supercars. The clean surfaces are enabled by the most advanced and effective aerodynamics ever seen on a road car, resulting in deliberately simple, beautiful lines and a timeless appearance.

The purity of the silhouette is broken dramatically when the pair of dihedral doors rise up and forwards, coming to rest high above the passenger cabin. Inside, the driver-centric approach is plain to see – from the central, jet fighter-like driving position, to the aerospace-grade primary and secondary controls arranged in an ‘ergonomic bubble’ around the driver.

Quality of materials, the utmost precision, and simplicity of visuals define the whole car, but nowhere is this more evident than inside the cockpit. British suppliers are responsible for every major component throughout the interior, as well as every facet of the car’s exquisitely-engineered underpinnings – an attribute insisted upon by Murray who was determined the T.50 would be a true British sports car.

From the record-breaking V12 engine, and best lightweight transmission, to the world-first aerodynamic package and the feather-light titanium throttle pedal, every element is 100% bespoke and crafted by a British company that leads in its field. Murray pushed each supplier to their limits to deliver ingenuity, the highest quality and of course new levels of lightness.

With a vision that the car, and every element of its componentry, would be considered ‘engineering art’, Murray set out to create a vehicle that surpassed all others, fostering new levels of pride and connection among owners. Every T.50 customer has the opportunity to meet Murray to discuss their car and personalise it inside and out. Part of this process includes a seat, steering wheel and pedals ‘fitting’ session – personalised to every owner – that will ensure the T.50 is ergonomically perfect and individualised for each discerning customer.

Murray: “Just 100 customers will share my vision, a car created to improve on the F1 formula in every conceivable way. With 30 years of technological and systems advancement, now, the time is right to design the greatest analogue driver’s car. I believe no other company could deliver what we will bring to market in 2022, producing this British supercar will be my proudest moment.”

The T.50 mission – Driving perfection

Murray: “From the first touch of the titanium throttle pedal to the V12 screaming at 12,100rpm, the driver experience will surpass any supercar ever built. No other road car can deliver the package of power, instant responsiveness and driver feedback in such a direct and focused way while remaining comfortable, refined and usable every day.”

At the heart of T.50 ethos is the ultimate, sensory-rich driving experience, which all starts with the central driving position. The ‘jet-fighter’ style seating position affords an unhindered view out of the cabin, offering the type of pure driving experience usually associated with a single-seater race car layout.

Murray insists that the engine contributes to at least 50% of a great driving experience. With this in mind, Murray set out to create the greatest ever V12. The bespoke Cosworth GMA unit hits the mark as the world’s highest revving, fastest responding, most power dense, and lightest road-going V12. In terms of aural enjoyment, the T.50 raucous 12,100rpm redline will certainly deliver on wow-factor. The car also features Direct Path Induction Sound – a system pioneered on the McLaren F1 and refined on the T.50 to channel the sound of the throttle-induced induction growl into the cabin.

A cold-air ram induction intake sits immediately above the driver’s head, and carefully crafted carbon fibre panels in the roof act as a loudspeaker, amplifying engine sound within the cabin. The system is actuated by throttle angle and not revs, meaning the T.50 is quiet and refined on part throttle, growing louder as the throttle opens.

Inside the cabin, all of the T.50’s ergonomically-placed analogue controls are beautifully weighted. From communicative steering, which delivers pinpoint accuracy, to the weighting of the six-speed manual transmission and titanium throttle pedal, the engineering focus has always been on driving perfection.

During testing, the manual H-pattern gearchange motion and weighting was honed meticulously. Signed-off personally by Murray, the T.50 provides ‘the ultimate gearchange’ – a tactile short throw with a narrow cross gate for smooth, crisp, satisfying gearchanges.

The T.50’s kerb weight of 986kg makes it the lightest supercar of the modern era, lower than the average supercar weight by almost a third. Thanks to the focus on lightweighting, the car offers unparalleled levels of agility, responsiveness and driver focus. The T.50 is a car that is created to be ‘alive’ at normal road speeds, not only when the revs climb past 10,000rpm. It will entertain and engage on low-speed daily trips, as well as when driving on the open road just for the thrill of it.

With minimal interference from driver aids the driving experience is left to shine – importantly, ESP and traction control, can be disabled entirely. The technologies that do influence performance – for example, the six aero modes enabled through active and interactive fan-assisted aerodynamics – enhance rather than numb the drive experience. The 400mm rear-mounted fan expands the car’s performance capabilities significantly versus an ordinary ground-effect supercar. In partnership with the active rear spoilers and interactive diffusers, the fan helps to increase downforce by 50% (in Braking Mode 100% more downforce is generated); reduce drag by 12.5%; add around 50PS to the car’s output, in combination with ram-air induction; and cut braking distance by 10m from 150mph.

Sitting prominently at the rear of the car, the fan is just one example of ‘engineering art’ on the T.50. Another, about which Murray feels passionately, is the engine. Murray detests carbon or plastic engine covers so, upon raising the twin gullwing openings that span the rear half of the car, the Cosworth GMA V12 engine sits proudly on display with its cam covers, primary exhaust manifolds and inlet trumpets all taking centre stage.

It is Murray’s pride in perfection that has shaped every facet of the T.50. Calling the exterior styling “a return to beauty” the clean lines and visual balance seek to deliver a timeless design that will help the T.50 age gracefully, a fresh and lasting celebration of motoring engineering – the ultimate analogue supercar.

Commenting on the journey so far, Murray said: “For the past 18 months, the T.50 team has lived and breathed the ethos of the car, accomplishing everything we set out to achieve and more. I couldn’t be happier with the car and the team – they’re by far the best I’ve ever worked with.”

T.50 supercar – key details

Focal point for every T.50 decision: The driver

T.50 is the most driver-centric supercar ever made. From the driver’s position right in the middle of the car, to the placement of controls, the sound of the engine, and the responsiveness of the throttle.

Overview

- T.50 breaks from performance-car convention, weighing significantly less than any other current supercar and delivering an unrivalled driving experience

- Gordon Murray Automotive is not chasing power or top speed figures

- Its engine is designed to deliver optimum performance, not to hit prescribed power, speed or acceleration target

- It has the most advanced and effective aerodynamics of any road car

- Non-committee-based vision and control enables purity of decision making

- Purity of design – no unsightly flaps / vents / wings

- Daily usability – comfort for three passengers with good luggage space, day-to-day refinement and practicality

Key points – Detail

- From January 2022, 100 exclusive customer cars will be built at Gordon Murray Automotive’s production site in the UK

- Price: £2.36m (before taxes)

- As the 50th distinct design by Professor Gordon Murray, CBE, the T.50 also celebrates Murray’s 50-year long career

- A true British supercar

- All engineering, design and styling is by Gordon Murray Design

- Powertrain, body, and chassis will all be made in the UK

- All major components are UK-sourced

Chassis and body

- Chassis and body constructed from high-grade carbon fibre

- Carbon tub monocoque provides exceptional stiffness and torsional rigidity

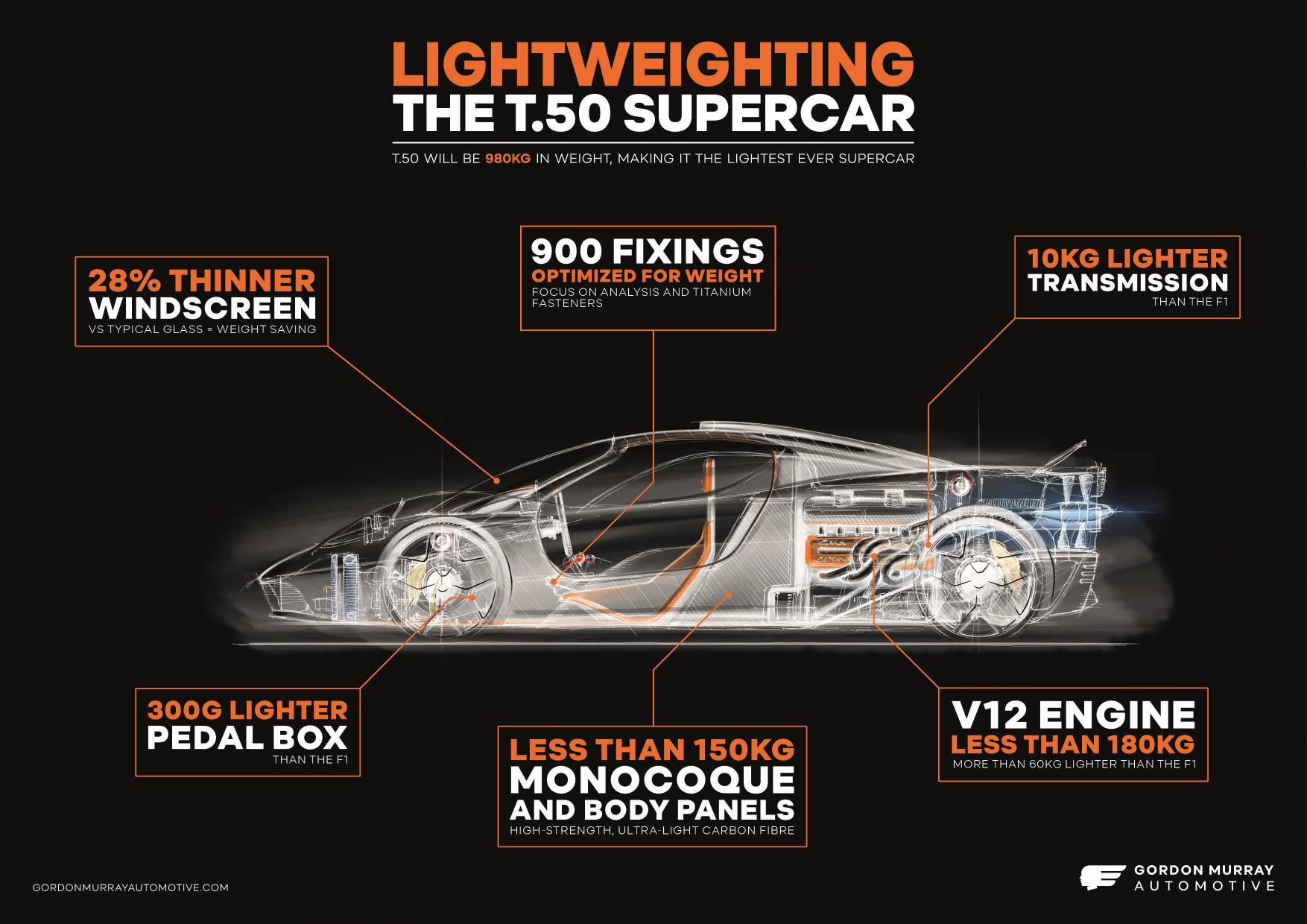

- Carbon fibre body panels ensure lightness – total body including monocoque weighs less than 150kg

- Monocoque construction and F1-style ‘passenger safety cell’ provides exceptional occupant safety protection

- Glazing is 28% thinner than typical glass delivering valuable weight saving

Aerodynamics

- The most advanced aerodynamics of any road car

- Unique 400mm ground-effect fan combines with active underbody aerodynamics and two dynamic rear spoilers to aid performance and help deliver an unrivalled driving experience

- Six aero modes enable driver to optimise dynamic and outright performance

- Auto / High downforce / Streamline / Braking / Test / V-Max Boost

- Streamline Mode – creates a ‘virtual longtail’

- V-Max Boost Mode and ram induction raise T.50 output to 700PS

- Auto / High downforce / Streamline / Braking / Test / V-Max Boost

Design

- Design combines purity and drama

- No unsightly vents, ducts, or flaps due to intelligent aerodynamic design

- Striking dihedral doors deliver drama alongside practicality for easy access

- Engineering art features throughout the car

Engine

- 100% bespoke 3.9-litre V12 Cosworth GMA engine

- Power: 663PS @ 11,500rpm

- Torque: 467Nm @ 9,000rpm (71% of max torque available from 2,500rpm)

- The highest-revving naturally-aspirated road car engine ever (12,100rpm)

- Most-responsive naturally-aspirated engine ever (28,400 revs per second pick-up)

- The most power-dense naturally-aspirated engine ever (166PS-per-litre)

- The lightest road-going V12 ever = 178kg

- The best V12 sound ever

- Engine fully on show beneath gullwing-opening ‘viewing gallery’

Transmission

- Xtrac manual H-pattern six-speed transmission

- Five close ratios, geared for acceleration, with a longer sixth ratio for cruising

- Casing engineered from aluminium, cast at just 2.4mm thickness

- Lightweight gearbox weighs just 80.5kg

Vehicle dynamics and lightweighting

- Total vehicle weight just 986kg – Almost a third lighter than a typical supercar (approx. 1,436kg). Dry weight 957kg

- Weight-to-power = 150.77kg per 100PS (typical supercar = 210kg per 100PS)

- Power-to-weight = 672PS/tonne (or >700PS/tonne with V-Max Boost Mode and ram induction)

- Forged aluminium double wishbone suspension, with forged aluminium uprights

- Simple rack and pinion steering setup engineered for driving purity with low-speed power assistance (LSPA)

- Semi-structural engine and transmission saves weight while retaining refinement

- Lightweight bearing carriers and hubs with one locking nut reduce un-sprung mass

- Brembo calipers and carbon ceramic discs for ultimate stopping power and braking feel

Interior

- Jet fighter-style central driving position ensures optimal visibility, balance and a totally-immersive driving experience

- Driver-centric controls

- Well-appointed, comfortable, refined

- Premium audio sound system – 10 speakers, 700W (nominal)

- Android Auto / Apple CarPlay with Bluetooth phone connectivity

Everyday usability and analogue features

- Comfortable seating for three adults

- Easy ingress and egress

- Class-leading, usable luggage space – up to 288 litres

- Refined cabin environment

- 120mm front and 140mm rear ride heights for practical everyday use

- Incredibly compact footprint – comparable to a Porsche Boxster

- Analogue rev counter and minimal controls / no column stalks or touchscreens

- No turbos, no hybrid – just an exquisitely engineered V12 engine

- ‘GT mode’ engine map for improved day to day drivability

T.50 Press Kit

Chassis and body – carbon fibre throughout achieves rigidity and lightness

The chassis and body of the T.50 are entirely constructed from high-grade carbon fibre. Creating inherent stiffness and torsional rigidity, the carbon fibre plays an important role in making T.50 the world’s lightest supercar.

Murray: “With the design of our T.50 supercar, we are taking the same focused approach that was applied to the design of the McLaren F1. Thanks to modern materials and 30 years of development, we have been able to deliver a far better all-round car in the T.50, while setting its weight at just 986kg, a full 150kg lighter than the F1.”

At the core of the T.50 is a lightweight carbon fibre monocoque. It has been constructed by UK-based company Formaplex and features novel, cutting-edge part-bonded carbon fibre an aluminium honeycomb core. This construction method gives the T.50 exceptional structural rigidity, which benefits handling, agility and ride comfort.

The intrinsic strength of carbon fibre ensures exceptional occupant safety in the event of a crash. The carbon fibre panels feature precisely engineered deformable areas and the car also uses an F1-style ‘passenger safety cell’. The rigidity and torsional strength negate the need for additional bracing or reinforcement – another area of weight-saving.

The exterior body panels are also constructed from cutting-edge carbon fibre – including the front clam, the sculpted doors and the car’s rear panels. Remarkably, the T.50’s body, including the carbon monocoque and all body panels, tips the scales at less than 150kg.

The Cosworth GMA V12 engine and manual Xtrac gearbox are also semi-structural, being mounted to the chassis. The powertrain is attached using an inclined axis shear mounting system (IASA). The engine sits on anti-vibration mounts to prevent unwanted noise and vibration entering the cabin, while enabling the effective management of braking, acceleration and cornering forces. This saves 25kg of chassis weight at the rear of T.50, compared to a traditional engine mounting system.

Completing the lightweight structure is an ultra-lightweight windscreen, which is 28% thinner than a standard glass windscreen.

Aerodynamics – the most advanced aerodynamics of any road car

Murray: “We were focused on achieving the purest possible form for the T.50, an objective we’ve achieved through world-first engineering innovations and active underbody aerodynamics.”

The T.50 takes road-car aerodynamics to entirely new levels, with Murray rewriting the rule book to significantly enhance the supercar’s ground-effect capabilities. To achieve unmatched aerodynamic performance, the car’s rear-mounted 400mm fan rapidly accelerates air passing under the car, forcing it through active boundary-layer control ducts that form part of the rear diffuser.

Through the application of two automatic and four driver-selected aero modes, the T.50 is capable of increasing downforce by 50%; reducing drag by 12.5%; adding around 50PS to the car’s output in combination with ram-air induction; and cutting braking distance by 10m from 150mph.

The fan and its associated ducting system improve on conventional ground-effect systems by actively managing both underbody and overbody airflow. This boundary layer control ensures the most effective interaction of airflow on top of, and below the car, balancing drag and downforce at all speeds.

This same fan-assisted aerodynamic enhancement was first used for the road on Murray’s F1 supercar. Few realise that two fans had been employed to pull air from under the car as these, far smaller, fans were hidden beneath each of the F1’s rear haunches.

The underbody airflow system not only enhances performance, but also allows purity of design for the car’s upper surfaces. Air flows over the top of the car undisturbed by unsightly vents, ducts, or flaps. The fan interacts with a pair of active spoilers at the rear, which can contribute to downforce or reducing drag, as required.

The fan is driven by a lightweight 48-volt motor, spinning at up to 7,000rpm. The unit’s design and underbody ducting does away with the need for a ‘skirt’ – like that used by Murray’s Formula One BT46B Fan Car. Vertical inlet ducts fitted with filters ensure no road debris can pass through the fan.

The T.50 features six different aero modes that optimise performance for different scenarios to balance traction and outright performance. The fan aero system has six modes – two are automatic (Auto and Braking), the remaining four (High Downforce, Streamline, V-Max Boost and Test Mode) are driver selectable:

‘Auto Mode’ is the car’s default setting. In this mode, the T.50 operates like an ordinary supercar with passive ground-effect downforce.

‘Braking Mode’ automatically deploys the rear spoilers to their maximum (+45 degree) angle when high levels of deceleration are required. The fan also operates simultaneously at high speed while the diffuser valves open. This function can double downforce, enhancing stability and grip, and shortening the 150mph-to-0mph braking distance by a full 10 metres. If sudden deceleration is required, and when aerodynamics could influence stopping distance, Braking Mode overrides all other modes.

‘High Downforce Mode’ is driver selectable and delivers enhanced traction – in this mode, the rear spoilers deploy at +10 degrees, diffuser valves open, and the fan spools up to increase downforce by 50%.

‘Streamline Mode’ cuts drag by 12.5% and boosts straight-line speed while also reducing fuel consumption and downforce. In this mode, the rear spoilers deploy to -10 degrees reducing base suction and drag. The diffuser valves close partially, stalling the diffuser and reducing downforce, which saves wheel travel to make the car more comfortable and efficient. It also sets the fan to operate at high speed, drawing air from the top deck to minimise drag while extending the trailing wake of the car, creating a ‘virtual longtail’ and producing 15kg of thrust.

‘V-Max Boost’ is the most extreme T.50 mode. It uses the characteristics of Streamline Mode, then uses the car’s 48-volt integrated starter-generator to drive the fan – freeing up power to the driveshaft. Combined with the ram-air induction, this boosts power to 700PS for short bursts of acceleration.

‘Test Mode’ operates when the car is stationary and is driver-selected. The fan spools up to its maximum 7,000rpm, the twin rear spoilers cycle through their full range of movement and the diffuser ducts / valves progressively open and close before returning to their rest position.

Monitoring the level of static and underbody pressure provided by the combined fan and diffuser system is possible via an interior gauge – displayed on the left-hand dashboard screen.

Design – purity enabled through engineering

Murray: “Next-level aerodynamics allow us to avoid the current supercar trend for exaggerated wings, vents and ducts. I was determined to create a clean and pure shape that would remain timeless, ensuring the T.50 will still look fresh in 30 years.”

The most dominant characteristics of the T.50 design are purity and balance. Enabled by the most advanced and effective aerodynamics ever seen on a road car, the exterior of the T.50 indulges Murray’s preference for simple, timeless lines and clean surfaces. The design does not rely on wings, vents, or ducts to emphasise its performance capabilities. Instead the eye is drawn to the compact, balanced proportions and driver-centric symmetry.

Stylistically, the T.50 is far from drama-free. The remotely-released dihedral doors rise up and forwards creating a striking visual impact, as well as easing ingress and egress even in tight parking spaces. These doors are joined by a pair of glass-topped gullwing rear openings that hinge along the spine of the T.50 to reveal the V12 powertrain – crucially free form covers – making it easy to view and to access for maintenance.

Also revealed, running alongside the engine bay on either side of the car are a pair of 90-litre vertical-load luggage compartments. With all four doors open, revealing two-thirds of the car’s interior, the T.50 looks other worldly – like a predatory winged insect preparing for flight. Both the right and left-hand doors and engine cover doors can be opened remotely via the key.

As with every element of the T.50, the importance of the driver is very much evident in the styling. One of the car’s most noticeable design features highlights the central driving positing and natural balance that confers. A central line runs from the nose-mounted mermaid badge and continues into the cabin, over the instrument binnacle and bisecting the driver’s seat and continuing up the rear bulkhead. Outside, the line is mirrored by a tiny spine that runs from the base of the ram-air intake to the top edge of the fan housing at the rear.

This line emphasises the car’s symmetry and innate balance. From the front, a pair of the latest, high-intensity LED headlights offer a clear nod of recognition to Murray’s iconic F1. Each headlight features a pair of deep-set, horizontally aligned rings that operate as daytime-running lights and indicator lights. The centre of each ring features the dipped and main-beam lights bettering the previous industry-leading supercar headlight for reach and throw by 15%.

A heat sink and series of slits beneath and above the headlights circulate air around each fitting to cool the unit. Many manufacturers hide this cooling function, whereas Murray played to his ideal of creating ‘engineering art’ by turning this functional requirement into a distinctive styling element.

Following the central line up and over the sharply raked windscreen leads the eye to a roof-mounted ram-air induction inlet, which feeds the V12 and adds extra horsepower as the supercar gathers speed. Front to back, the roof is glazed either side of the central spine creating an incredibly spacious feeling interior and a sleek exterior appearance. As the spine falls towards the rear of the car the glazing continues, affording a glimpse of the V12 engine beneath its carbon fibre air box.

The rear deck is heavily sculpted to aid airflow towards the active spoilers. From the rear glazing, air flows beneath the rear deck to assist engine oil cooling – in streamline mode this air is channelled and ejected by the rear-mounted fan. The black inlet contrasts with the painted body and merges with the black fan housing that protrudes dramatically above the level of the rear deck and out beyond the trailing lip of the twin active spoilers that sit either side of the 400mm fan outlet.

Flanking the fan body are dual 80mm diameter exhaust outlets that sit within a black grille featuring an elongated-hexagon pattern that spans the full width of the rear end. At the rearmost outer corners of the car, circular red LED tail-lights draw the eye with their 3D transparent forms reflecting light outwards to create a stylish focal point. These units also act as rear turn indicators.

The profile of the T.50 is distinguished by the radiator exit duct behind the front wheel, the split side windows and the forged aluminium alloy wheels (19-inch front / 20-inch rear). Each side of the car also carries the name of the automotive division’s sister company: ‘Gordon Murray Design’ the business responsible for all of the car’s design and engineering.

In terms of overall proportions, the T.50 is extremely compact. Its 4,352mm length and 1,850mm width belie the generous interiors space, with room for three occupants and up to 288 litres of belongings. The addition of rear-view cameras (to be finalised during the next stage of the development process) will add no extra width and allow the car to avoid the weight, drag and unsightly clutter of external mirror housings. A third camera will sit in the centre spindle of the fan, providing a perfect rear view for reverse parking.

The Gordon Murray Automotive ‘mermaid badge’ sits proudly on the nose of the T.50. The company’s ‘new’ badge is probably the oldest automotive logo in the world. It has been in use by the Murray family since the 12th century. Also, acknowledging his family’s Scottish heritage, the blue, red and green colouring is the Murray clan tartan.

Engine – The greatest road-car V12 ever made

Murray: “To be truly remarkable, an engine needs to have the right characteristics: highly-responsive, an amazing sound, engaging torque delivery, free-revving, and it has to be naturally aspirated. For all those reasons, the engine in the T.50 was never going to be anything other than a V12.”

The 3.9-litre T.50 engine delivers maximum power (663PS) at 11,500rpm, on its way to a 12,100rpm redline. The Cosworth GMA V12 not only promises screaming high-end power, it is also extremely tractable for everyday driving. The maximum torque figure of 467Nm is produced at 9,000rpm, while the pick-up is a record-breaking 28,400 revs per second.

The T.50 has the highest power density (166PS-per-litre) of any road-going V12. It is also the lightest ever made thanks to a combination of exceptional design and lightweight materials (aluminium, steel and titanium) resulting in a total engine weight of just 178kg.

The meticulously designed and engineered powerplant draws upon the immense experience of Cosworth and Murray himself. It is the most engaging, characterful and driver-focused V12 engine ever produced.

Layering Murray’s depth of knowledge with Cosworth’s immense expertise in high-performance engines is what takes the T.50 V12 to another level. The name Cosworth is synonymous with racing – from Formula One, to rally, to IndyCar – as well as production of some of the most admired and successful supercar engines in the world.

With a focus on driver engagement, the T.50’s engine will be the highest-revving and most responsive naturally-aspirated engine ever fitted to a production road car. The V12 engine revs freely to a road-car record of 12,100rpm. Measured in revolutions gained per second, the T.50 will pick-up revs at 28,400 revs per second enabling it to hit its redline from idle in just 0.3 of a second.

Fed by a roof-mounted cold-air ram induction inlet, the T.50 powerplant delivers 71% of its peak torque from 2,500rpm, with its maximum (467Nm) achieved at 9,000rpm. This usability, and the outright performance of the engine is coupled to another major achievement: the Cosworth GMA unit produces the highest power density of any naturally aspirated road car engine – 166PS-per-litre.

Packing this amount of power into the world’s lightest road car V12 (just 178kg) required yet more innovation from Murray and the Cosworth team. To achieve Murray’s weight target, the block is made from a high-strength aluminium alloy and the connecting rods, valves and clutch housing are titanium.

Focusing again on the driving experience, Murray strived for the engine to have very compact external dimensions and the lowest possible centre of gravity. Here, reducing the F1’s 125mm crank height was the goal, a feat more than achieved by the Cosworth team – the T.50’s crank sits just 85mm from the bottom of the engine.

This accomplishment contributes in a very meaningful way to the dynamics of the T.50. The low centre of gravity means less pitch during cornering and braking, less squat and dive, plus better transient handling, meaning the T.50 will remain composed and balanced even at the extremes of performance.

Beneath the car’s two rear gullwing openings, Murrays motorsport heritage influences the appearance of the Cosworth GMA V12. Inspired by race car engines, it uses gear-driven ancillaries for lightness, with the added benefit of a clean and uncluttered engine bay. Murray was determined that the engine should be devoid of unsightly belts. All of the ancillaries are carefully positioned out of sight leaving the block heads, primary exhaust manifolds and inlet trumpets centre stage.

As well as effectively being an engineering work of art, T.50’s engine is semi-structural, providing much of the rigidity and weight saving found in a race car, without compromising driver comfort and cabin refinement. The semi-structural layout saves weight and increases stiffness while avoiding the noise, vibration and harshness penalties typically found with fully structural units, which increase cabin noise and hamper ride comfort.

As part of the early development process, the Cosworth team surpassed efficiency and emissions requirements and completed plans for two engine maps. These driver-selectable modes ensure the T.50 is not only the ultimate driver’s car, but is equally at home as a GT or a daily driver. While the engine offers usability and high-performance in either mode, ‘GT mode’ limits revs to 9,500rpm and with 600PS available, making the car even easier to drive around town.

If the driver selects ‘Power mode’, the full breadth of the car’s ability is unleashed, utilising all 663PS, and accessing the engine’s full 12,100rpm rev range. In this mode in particular, it promises to be one of the best sounding road car engines ever made – achieved partly through the extensive rev-range, but also influenced by the car’s Direct Path Induction Sound engineering, which channels the sound of the fabulous V12 into the cabin.

The T.50’s power and traction can be controlled by an electronic stability programme (ESP) and traction control system. With the driver aids engaged, the systems allow a progressive driving experience, while providing the driver greater confidence to explore the car’s limits in all weather conditions. Importantly, both systems can be switched off entirely should talented drivers want to fully explore the car’s capabilities.

Transmission – bespoke and lightweight – the ultimate gearshift

Murray: “The car’s six-speed H-pattern manual transmission is a tribute to Xtrac’s skill, continuing our focus on driver engagement. The gearchange motion and weighting was honed meticulously until we achieved the perfect end result. The outcome is a narrow cross gate and a short throw. It delivers slick, crisp gearchanges – truly a joy for the driving enthusiast.”

Being totally bespoke, it was possible to optimise every component of the gearbox for weight. Remarkably, the Xtrac team created a super-strong but extremely light aluminium housing that was cast at just 2.4mm thickness – resulting in a gearbox that not only met strict packaging requirements within the car, but also weighed in at just 80.5kg.

The transmission features five close ratios, geared for acceleration, with a longer sixth ratio for cruising. Reverse is selected having first flicked the red ‘lockout’ switch set next to the titanium gear lever.

Vehicle Dynamics – a focus on lightweight

Murray: “Weighing just 986kg, the T.50 undercuts the average supercar weight by almost a third. A heavy car can never deliver the dynamic attributes of a lighter car – even if it has the same power to weight ratio. While it is possible to disguise a heavy car’s dynamic capabilities with complex active suspension and sophisticated electronics, the agility, responsiveness and reward of a lightweight vehicle simply cannot be matched.”

In designing the T.50, Murray applied one of his core supercar philosophies, reversing the traditional focus on power-to-weight, to instead consider the vehicle’s ‘weight-to-power’ ratio. In the T.50, every 100PS has to propel just 150kg of car, whereas for the typical supercar (1,436kg with 693PS) the weight it has to shift is 40% higher, at 207kg. It is this weight-to-power calculation that drives the development of the T.50, with every component designed and engineered to achieve the lowest possible weight.

Powered by its 663PS V12 engine, the lightweight T.50 sets a challenging benchmark for rival supercars. To match the T.50’s 672PS/tonne, the typical 1,436kg supercar would need almost 300PS more power. But the 963PS required to match the T.50 on paper would add cost, complexity, and require larger, heavier components to handle the extra power.

Avoiding the weight-gain spiral caused by chasing top speeds and highest power output figures, Murray benchmarked the lowest possible weight for every component, right down to individual nuts and bolts. A key area where weight was minimised is the T.50’s fully carbon fibre monocoque and body panels, which total less than 150kg. Inside, three racing-inspired seats are also constructed using carbon fibre, with the centrally positioned driver’s seat and the passenger seats that flank it having a combined weight of just 13kg.

Throughout the early development process, weekly ‘weight watchers’ meetings at Gordon Murray Automotive scrutinised the weight of every component. Even the diameter and length of approx. 900 fixings was optimised to cut weight, taking account of the forces to which each would be exposed.

For the Gordon Murray Automotive team, no saving in weight was too insignificant, their focus on lightweighting has been unwavering. Every innovation, every iterative improvement supports the lightweighting strategy that helps create the purest, lightest, most driver-focused supercar ever.

This central mission promoted simplicity of construction and no compromise was tolerated, no expense was spared. The low total weight of the car means that the T.50 can use forged aluminium alloy double-wishbone rising rate suspension front and rear, with no additional interference required from heavy electric or hydraulic suspension components. The steering system is similarly pure, the simple rack-and-pinion setup is unassisted at speed, with the aim of ensuring a truly engaging driver feel, while there is low speed power assistance (LSPA) for parking.

The suspension and steering works in partnership with the Michelin Pilot Sport 4 S tyres (235 / 35 R 19 at the front and 295 / 30 R 20 at the rear). Chosen by Murray to avoid costly replacement of bespoke rubber and specified for superior all-round performance, the Michelin tyres are another weight-saving move as they can be far smaller and narrower than a typical supercar tyre due to the sprightly weight of the T.50.

T.50’s body and chassis are constructed almost entirely from carbon fibre, which ensures incredible stiffness, such that no additional bracing is required in the car. The structural stiffness ensures optimum handling, agility and ride comfort.

The T.50 also boasts race-car levels of agility and driver focus thanks to its low centre of gravity – afforded, primarily, by its semi-structural engine, which sits low in the chassis and delivers a very low polar moment of inertia.

Another of consideration for the vehicle’s dynamics was minimising un-sprung mass. Here, Murray applied a host of tactics that combine to keep weight down. The wheels, hubs, and suspension arms are all ultra-lightweight. The wheels are forged from a lightweight blend of aluminium alloy (front 7.8kg, rear 9.1kg), as are the suspension uprights and wishbones. While, for ultimate weight saving, the car’s hubs and bearing carriers mimic those of an F1 car, with a single locking nut, dramatically reducing the amount of material needed for their construction.

The T.50 is braked using the latest-generation Brembo six-piston air-cooled aluminium alloy Monobloc callipers on the front and four-piston air-cooled aluminium alloy Monobloc callipers on the rear. Optimum stopping power, and further weight saving, is ensured by pairing them with Brembo carbon ceramic brake discs (front 370mm x 34mm / rear 340mm x 34mm). The latest Brembo advancements enable these discs to be smaller than similarly-powered vehicles that don’t benefit from this newly-released technology. The car is also equipped with an anti-lock braking system.

The T.50’s braking setup will be subject to a rigorous testing and real-world fine-tuning regime during the forthcoming development period. The final outcome will be the ultimate braking system for the enthusiastic driver, with low levels of servo assistance making ‘heel-and-toe’ gear changes easy and natural. The carbon ceramic discs are calibrated to engage progressively and with a firm pedal feel – and will also naturally resist fade and a ‘long’ pedal during enthusiastic driving and repeated deceleration from high speeds.

Interior – a jet fighter cockpit for three

Murray: “Everything about the interior starts with the driver – the central driving position is the clearest demonstration of this approach. Building on this starting point, every control is arranged within easy reach of the driver. Purity of design was our goal, with the utmost quality applied to every element. The cabin is spacious and refined, making the T.50 exceptionally capable of traversing continents in comfort.”

From the outside looking in, the T.50 appears to be a single seater racing car. With intentional focus on the driver, Murray specified the driver’s seat to stand out in a vivid colour, while the two passenger seats that flank it are trimmed to blend in with the rear bulkhead.

As the dihedral doors lift, they present a wide opening that grants easy access to the cabin for driver and passengers. The design of the carbon fibre monocoque moves the need for torsion beams from the centre of the passenger compartment to the outside of the chassis, meaning the floor is free from obstruction.

Each customer will have a personalised seat fitting during the specification process, at the same time adjusting the steering wheel height and reach, and fine tuning the set-up of the pedal box.

In keeping with much of the rest of the car, each pedal is an engineering work of art. Milled from solid aluminium for strength and lightness and laser-etched with the T.50 name, the clutch and brake pedals both feature a web-like pattern to save weight and provide an anti-slip surface. The accelerator pedal is crafted from solid titanium to deliver the lightest, strongest pedal that delivers ultimate control and sensitivity to the driver.

To the right of the driver, the titanium gearstick sits on an arm that extends alongside the driver’s seat. The underside of the arm ‘floats’ above the cabin floor to reveal the expertly-crafted titanium gearchange mechanism.

The arm itself features a number of controls including the drive mode selector, infotainment rotary control, and most importantly a centrally-positioned engine start / stop button, sheathed beneath an anodised red jet fighter-style ‘missile switch’ cover. At the frontmost tip of the arm is an individually laser-etched chassis plate denoting the vehicle build number.

Once seated in the central driving position, the three-spoke carbon fibre steering wheel is pleasingly narrow-rimmed to afford a firm grip and transmit abundant feedback. Behind the wheel, a left- and right-hand paddles enable the driver to sound the horn or flash the headlights without taking their hands off the wheel. There are no touchscreens and no stalk controls – even the indicators are operated by thumb-buttons on the steering wheel’s horizontal spokes.

Every control is analogue, every display is designed for functional clarity, every primary and secondary control switch is satisfyingly tactile and ergonomically positioned for ease of use.

Front and centre in the driver’s view is a large (120mm) analogue, flood lit rev counter – its needle milled from aluminium. Either side of the steering wheel, three aerospace-grade aluminium rotary switches are positioned within easy reach. On the right, the switches control the heating / ventilation and air conditioning, while to the left the two lower controls are for wipers and lights. The top-left dial is the most intriguing and unique – marked with a graphic of the T.50 fan, this configures the four driver-selectable aero modes.

Everyday usability – the ultimate supercar that’s easy to live with

Murray: “Comfortable, refined, spacious and easy to drive – not a typical description for a supercar with the capabilities, power or driver focus of the T.50. I’ve designed this car to be used every day, with almost 300 litres of luggage and storage space, a premium stereo, and excellent air conditioning. From its exceptional visibility and compact footprint to ease of ingress and egress, the T.50 rewrites the supercar rule book for usability.”

The Gordon Murray Automotive team evaluated ease of access to the T.50 at length. More than 40 people of all ages and sizes took part in an assessment of a range of different seating permutations. The car’s dihedral doors were chosen to enhance the ease of getting in and out, while the sill of the carbon tub sits low to the ground and the flat cabin floor is free from obstructions across the full width of the car.

Once inside, visibility out is excellent, in no small part due to the central driving position. The car’s compact proportions mean that its footprint is comparable to that of an average C-segment hatchback, making it easy to park and place on narrow roads or in urban environments.

Passengers have a large amount of usable storage space, with a combined 30 litres of interior stowage across five compartments – one above each passenger’s footrest, another under each passenger seat, plus one behind the driver’s headrest. Set within the left and right rear haunches of the car are vertical-load luggage compartments, each with around 90 litres of capacity – comfortably swallowing a flight case each side. When carrying three passengers, the luggage capacity totals 228 litres. However, by using a specially made suitcase that is sculpted to the shape of the passenger seat, two occupants can enjoy 288 litres of luggage / storage space.

In terms of daily use, the T.50 is quiet and easy to pilot. The engine map has two states of tune, one ‘Power Mode’ for maximum revs and the full 663PS, and a ‘GT Mode’ that limits revs to 9,500rpm and power to 600PS – ideal for urban commutes or relaxed touring.

Ensuring comfort and practicality around town, the T.50 has a 120mm front and 140mm rear ride height allowing it to easily clear speed bumps and other road furniture without damaging the car’s bodywork or causing discomfort.

Technology – all the driver essentials, no driver distractions

Every display in the T.50 is simple. White graphics on a plain black background ensure ease of use and quick recognition for the driver with minimal distraction. Even the rear-view displays are optimised for the driver, offering a better field of vision than mirrors and weighing significantly less.

Delivering a premium audio experience was a key element of the T.50 brief. Here Murray stuck to his key principals for the car; lightweight, highest-quality and British. Again, bucking industry trends, Murray enlisted high-end audio specialists Arcam to create a 700W nominal 10-speaker 100% bespoke sound system for the T.50.

Aligning with the car’s lightweight characteristics, the whole system weighs just 3.9kg and connects wirelessly to the driver’s phone to stream audio. The T.50 also uses Android Auto / Apple Car Play for all Bluetooth phone and navigation functions – which are displayed on the infotainment screen to the right of the rev counter.

Customer experience – the return of a true supercar owner’s experience

T.50 buyers have received bespoke and personalised service, from the first expression of interest and throughout the purchase, specification and manufacturing process. That same approach will continue for the duration of their ownership.

During the car’s development, owners have been given first sight of vehicle designs, engineering milestones and project updates. Moving closer to the car’s 2022 manufacturing date, customers will be invited to set up their car to fit them perfectly, while customisation of colours and interior will allow individualisation of the strictly limited 100 T.50 models.

Murray has met or spoken to every buyer and will hand over every car collected from the Gordon Murray Automotive’s UK customer reception centre. Around the world T.50 owners will have access to a service network in the UK, US, Japan, and Abu Dhabi – with a ‘flying technician’ service supporting these and all other markets.

Throughout the build of their car at Gordon Murray Automotive’s UK production base, customers will be kept informed of the status of their car and will have the option to visit their car during the build. Following collection, owners will be offered tailored experiences to continually enhance their ownership of the world’s most driver-centric supercar.

POWERED BY THE GREATEST ROAD-CAR V12 EVER MADE

Maximum driver engagement through optimised power, weight and responsiveness

- 50 powerplant will be world’s highest revving, fastest responding, most power dense, and lightest naturally aspirated V12 road car engine

- Driver-focused, characterful 12-cylinder unit is inspired by high-revving Formula One engines

- 100% bespoke, super-lightweight Cosworth GMA V12 doesn’t share a single part with any other engine

- Engineering art: engine fully on show beneath gullwing ‘viewing gallery’

- Bespoke Xtrac manual ‘H-pattern’ transmission is light, compact and delivers the best shift action of any road car

Ahead of the global premiere of the T.50 supercar on 4 August (17:00 BST), Gordon Murray Automotive has confirmed full details of the bespoke Cosworth GMA V12 engine that will power the new model.

The 3.9-litre powerplant will be the highest revving, fastest responding, most power dense, and lightest naturally aspirated V12 road car engine ever. Meticulously designed and engineered, the powerplant combines the immense experience of Cosworth and Murray to be the most engaging, characterful and driver-focused V12 engine ever produced.

Brief: A Formula One engine for the road

Professor Gordon Murray CBE: “More than half of any truly great driving experience is delivered by the engine, so right from the start I set the highest possible benchmark – to create the world’s greatest naturally-aspirated V12.

Professor Gordon Murray CBE: “More than half of any truly great driving experience is delivered by the engine, so right from the start I set the highest possible benchmark – to create the world’s greatest naturally-aspirated V12.

“To be truly remarkable, an engine needs to have the right character; highly-responsive, an amazing sound, engaging torque delivery, free-revving, and it has to be naturally aspirated. For all those reasons, the engine in the T.50 was never going to be anything other than a V12.”

A key part of the brief was to keep the capacity of the T.50’s V12 as small as possible. The original inspiration for the engine stemmed from the 3.3-litre V12 powering the legendary Ferrari 250 GTO – small capacity, characterful and powerful. With a clear view on the required acceleration and torque, and the goal of a sub-1,000kg total vehicle weight, Cosworth proposed the capacity could be just 3.9-litres while still achieving supercar performance.

Murray’s brief was clear – the engine had to be light. It had to have the fastest response time of any engine ever built for the road, aping the targets set for his illustrious McLaren F1. It had to be high revving too, and for this characteristic Murray benchmarked the record set with his Light Car Company ‘Rocket’, which revved to 11,500rpm. And to top it off, it had to be characterful, sound superb, and look good – a clean design with no coverings or belt-driven ancillaries.

Not only does the T.50’s V12 promise screaming high-end power, it is also tractable for everyday driving. The maximum torque figure of 467Nm is produced at 9,000rpm, but key to ensuring day-to-day driveability is that 71% of the engine’s torque will be produced from as low as 2,500rpm.

In its most extreme aerodynamic setting – Vmax Mode – the T.50 is optimised for outright performance. Here, while gaining around 50PS from the car’s 48-volt integrated starter-generator, the car combines motorsport slipstream technology and ram air induction to boost performance even further.

Experience: Murray + Cosworth = ultimate motorsport and supercar collaboration

Having started his career as an engine designer, Professor Murray was keen to have a significant influence over the design of the T.50 engine. The powertrain also draws on Murray’s learnings from Formula One racing and his creation of the McLaren F1.

Murray: “Ultra-light components, intelligent packaging and a really fast engine response all come directly from my 20 years’ experience in Formula One. It also informs how everything is driven – the T.50 has no belts, it’s all gear-driven – a direct inheritance from the pinnacle of motorsport.

Layering Murray’s depth of knowledge with Cosworth’s immense expertise in high-performance engines is what takes the T.50 engine to another level. The name Cosworth is synonymous with racing – from Formula One, to rally, to IndyCar – as well as production of some of the most admired supercar engines in the world.

Bruce Wood, Cosworth Managing Director: “The criteria and benchmarks set by Gordon for the T.50 engine comprised one of the toughest engine briefs we’ve ever taken on. It pushes the boundaries in every direction and it is a genuine thrill for everyone at Cosworth to be part of what will surely become as fabled a vehicle as Gordon’s McLaren F1 before it.

“The programme has taken Cosworth to new heights and, although only time will tell, it already feels like the GMA V12 has the potential to be one of the most iconic engines of all time.”

In devising his brief for the T.50 engine, Murray drew on his experience working with the 3.5-litre Honda RA121E V12 engine that powered the McLaren MP4/6 Formula One cars in the early nineties. According to Murray, this engine was the peak of the Formula One V12 powerplants in terms of its performance, balance and weight.

The T.50 powertrain also draws inspiration from the BMW S70/2 V12 developed for Murray’s highly revered McLaren F1, which to many remains the ultimate supercar engine. But for Murray there were improvements that could be made.

Murray: “Above all else, I wanted it to look clean like the BMW S70/2 engine, which had no carbon or plastic covers. It was just inlet trumpets, cam covers, exhaust block and heads, and a few belt-driven ancillaries that I managed to squeeze out of sight. In designing the T.50 V12, I wanted it to be the antidote to the modern supercar where you can’t see the engine beneath carbon covers.”

Even today, the F1 is considered to be one of the finest driver’s cars money can buy – but Murray always felt that the S70/2 engine could have been improved. The BMW unit is a much lower revving engine, meaning that for Murray, just as the sound began to build, the next gearchange cut the experience short.

Creation: a 100% bespoke V12 that may never be surpassed

Murray: “I started my career as an engine designer, so conceiving and specifying the 100% bespoke 3.9-litre V12 for the T.50 was such a joy. Having a blank sheet of paper and setting out to create the world’s best, highest-revving, most beautifully crafted, amazing sounding engine is something I’ve been waiting to do for years!”

The highest-revving, most responsive naturally aspirated engine ever

The record for highest-revving engine was previously held by another of Gordon Murray’s creations – the 11,500rpm Light Car Company’s ‘Rocket’. This record will be beaten by the T.50 V12.

Beyond the record-setting and the totally-unique experience of driving a car that revs this high, the logic behind the 12,100rpm is to maximise driver engagement with, and appreciation of, the raw power available as revs increase.

The T.50 engine will deliver maximum power (663PS) at 11,500rpm. But driver enjoyment won’t kick in only at the far end of the rev range. This engine will also be the most responsive naturally aspirated road-car engine ever produced. Measured in revolutions gained per second, the T.50 will achieve mind-boggling responsiveness, picking up at 28,400 revs per second (the F1 engine’s equivalent is around 10,000 revs per second). To put the T.50 figure into context, this means that its V12 can rev from idle to its 12,100rpm redline in 0.3 of a second. Another figure that sets a new benchmark and is unlikely to ever be surpassed with a road car.

The most power-dense naturally aspirated engine ever

The T.50 engine produces the highest power density of any naturally aspirated road car engine ever made – 166PS-per-litre. This record, coupled with the lightness of the unit, places this engine right at the pinnacle of naturally-aspirated powertrain development.

The lightest road-going V12 ever

The T.50 V12 had to be light, to align with Murray’s ethos for the whole car. To achieve the lowest weight possible the block in the T.50 is made from a high-strength aluminium alloy, the crankshaft is made from steel and weighs only 13 kilograms, and the connecting rods and valves are made from titanium – as is the clutch housing. This all contributed to engine weight of just 178kg – yet another road-car record.

Murray: “Good design throughout kept engine weight low, while our refusal to cut corners in terms of quality, packaging, layout, and of course performance ensured we surpassed all of our goals.”

The best V12 sound ever

Delivering on a key element of the brief, the naturally-aspirated powerplant in the T.50 promises to be one of the best sounding road car engines ever made.

Part of the aural enjoyment will be created by the car’s screaming redline, but the team behind the T.50 have also found additional ways to ensure the sound of the engine delivers maximum driver enjoyment. The T.50 features Direct Path Induction Sound – a system pioneered on the McLaren F1 and refined on the T.50 to channel the sound of the raucous V12 into the cabin.

The cold-air ram induction intake sits immediately above the driver’s head, and is crafted – with varying thicknesses of carbon fibre in the roof that act as a loudspeaker – to amplify engine sound in the cabin. The beauty of the system is that it is actuated by throttle angle and not revs, this means the T.50 is quiet and refined on part throttle and grows louder as the driver pushes through half-throttle and beyond.

Murray: “You can never get a great sound from a turbocharged engine. The T.50 engine sound is going to be phenomenal. The intoxicating growl that drivers love is introduced as the throttle angle increases, the sound intensifies as the induction sound kicks in, then as you push towards the upper end of the rev range the V12 will sing like nothing else on the road.”

Engineering-in optimal driver enjoyment

The T.50’s engine is semi-structural, providing much of the rigidity and weight saving found in a race car, without compromising driver comfort and cabin refinement. The Gordon Murray Automotive team opted for a semi-structural engine to reap the rewards of weight saving and stiffness while avoiding the NVH downsides of fully-structural units, which struggle with cabin noise and ride-comfort.

In the T.50, the suspension wishbones are connected to the gearbox casing, which manages the forces associated with braking, accelerative reaction and lateral cornering forces. Lateral movement of the engine is limited by two rubber-mounted trapezoidal links from the gearbox. Looking at the rear of the car, these links meet at the ground plane, forming a triangle and adding stiffness while limiting any lateral movement. Meanwhile, fore and aft movement of the engine is kept in check by snubber bushings on the engine mountings that allow the degree of engine movement to be tuned during maximum acceleration and braking.

Low centre of gravity

The size, weight and well-considered positioning of the T.50’s engine all play a key role delivering the car’s overall low centre of gravity. Compact dimensions were critical. Murray’s aim was to better the F1’s 125mm crank height, a feat more than achieved with the new supercar’s crank, sitting just 85mm from the bottom of the engine. This is largely thanks to Cosworth’s innovative design, which scavenges oil using windage to ensure that the crank sits as close to the sump line as possible.

This improves the vehicle dynamics in a few key areas. The low centre of gravity means less pitch during cornering and braking, less squat and dive and better transient handling. The overall effect cannot be overestimated for the T.50’s vehicle dynamics.

Engineering art: The beauty of simplicity

The average modern supercar is festooned with plastic and carbon fibre covers – the T.50 is not. In many ways the car serves as the antithesis to the modern supercar, presenting a clean and contemporary celebration of the engine, evocative of the stripped-back approach evident with 1960s performance cars.

The T.50’s engine bay is designed to present the engine in all its glory. Housed beneath duel ‘gullwing’ openings, which both pivot from the car’s central spine, the engine sits proudly without covers to focus on the raw beauty of the V12.

Inspired by race car engines, the Cosworth GMA V12 uses gear-driven ancillaries for lightness, with the added benefit of a clean and uncluttered engine bay, devoid of unsightly belts. All of the ancillaries are carefully positioned out of sight leaving the block heads, primary exhaust manifolds and inlet trumpets centre stage.

Murray: “Every component on this car is a piece of engineering art, and the engine is no exception. I wanted the engine to look like a modern interpretation of a 1960s V12. If it wasn’t the beating heart of the T.50 it would make a fabulous, sculptural modern-art installation.”

The world’s best gearchange – six-speed close-ratio transmission

Created by British transmission experts Xtrac, the short-shifting six-speed manual gearbox in the T.50 is staggeringly lightweight. Weighing just 80.5kg, the bespoke unit was created to meet the brief to offer ‘the best gearchange in the world’ – for maximum driver enjoyment.

Murray: “Maximising the driver’s connection with the T.50 was central to our decision-making. So, matching the V12 engine to an exquisite short-shifting manual gearbox was an easy decision to make.”

Brief: Super-light, highly-compact, zero compromise on shift quality

As with the powertrain, the brief for the T.50’s gearbox was similarly comprehensive. It had to be extremely lightweight while remaining a robust semi-structural component; it should have an outstanding gearshift feel; and it had to meet Murray’s exacting, compact packaging specification. Murray insisted the gearbox be both short and narrow to fit into the car’s compact dimensions and to avoid any interference with car’s pioneering ground-effect aerodynamics.

A totally-bespoke, transmission of exceptional quality – the ultimate gearshift

The six-speed manual ‘H-pattern’ short-throw gearbox that resulted from the brief is a piece of exceptional design. Being totally bespoke, it was possible to optimise every component for weight. Remarkably, the Xtrac team created a super-strong, but extremely light aluminium housing that was cast at just 2.4mm thickness.

During early testing, the gearchange motion and weighting was honed meticulously, with adjustable actuators fitted to all parts of the gear linkage. Signed-off personally by Murray, the painstaking testing process ensured that the end result was perfect in every way.

The final gearbox has a short throw and a narrow cross gate for smooth, crisp gearchanges. It features five close ratios, geared for acceleration, with a longer sixth ratio for cruising.

Engine and transmission – Technical specification

Engine

Type number Cosworth GMA

Configuration V12 semi-structural

V-angle 65°

Capacity 3,994 cc

Bore 81.5 mm

Stroke 63.8 mm

Compression ratio 14:1

Max power 663 PS @ 11,500 rpm

Power to weight ratio 672 PS per tonne

Weight to power ratio 150 kg per 100 PS

Max torque 467 Nm @ 9,000 rpm

Flexibility 71% of max torque @ 2,500 rpm

Maximum rpm 12,100 rpm

Valve train Gear driven double overhead camshafts

Inclined axis 4 valves per cylinder – variable valve timing on inlet / exhaust

Induction system RAM induction airbox – 4 throttle bodies – Direct Path Induction Sound

Exhaust system Inconel and Titanium

Lubrication system Dry sump

Cooling system Water-cooled – twin aluminium front radiators

Oil cooling system Single aluminium rear radiator

Ignition system 12 individual coils 12-volt

Starter/alternator 48-volt gear driven integrated starter / generator

Exhaust emission control 4 catalytic convertors with Lambda sensors and secondary air injection

Engine block Aluminium alloy

Cylinder heads Aluminium alloy

Connection rods Titanium

Valves Titanium

Total engine weight 178 kg

Engine mounting Semi-structural-inclined axis shear mounting (IASM)

Power density 166 PS-per-litre

Transmission

Configuration Transverse with high-speed bevel gears and spur gear final drive

Speeds 6 speeds + reverse: full synchro mesh

Gear change Manual H pattern with reverse lock-out

Differential Limited slip (Salisbury)

Clutch 184 mm diameter – Triple plate carbon silicone and titanium

Drive line Tripod joints and gun drilled drive shafts

Casing Aluminium alloy

Lubrication Pumped lubrication

Oil cooling Single aluminium alloy radiator

Ratios

First 2.833:1

Second 2.095:1

Third 1.577:1

Fourth 1.226:1

Fifth 0.971:1

Sixth 0.744:1

Input bevel 1.688:1

Final drive 3.176:1

Optional overdrive (6th) 0.595:1

Weight 80.5 kg

A FOCUS ON LIGHTWEIGHT

- Murray’s ‘weight-to-power’ ethos shapes performance and handling of T.50

- Murray: “a heavy car can never deliver the dynamic attributes of a lighter one”

- T.50 undercuts typical supercar weight by almost a third

Last year, Gordon Murray Automotive (GMA) announced details of its plan to create the world’s lightest, most driver-focused supercar. Setting the benchmark so high required new levels of innovation, and a shift away from the current supercar trend of ever-greater power, speed and – inevitably – weight.

Revealing a total vehicle weight of just 980kg, the GMA team undercut the typical supercar (approx. 1,436kg*) by almost a third. To achieve this engineering feat, the team chose not to present a stripped-back track vehicle, but to deliver owners a car that is comfortable, practical and drivable every day.

Commenting on his ‘every component counts’ approach to lightweighting, Professor Murray said: “Designing a lightweight sports car does not come from specifying exotic materials alone, it comes from a state of mind, from absolute focus and control, and from a deep understanding of lightweight, optimised design.”

Weight-to-power, not power-to-weight

One of Murray’s core philosophies is that there is a huge difference between power-to-weight ratio and his own design perspective that considers a vehicle’s ‘weight-to-power’.

In the T.50, every 100hp only has to propel 150kg of car, whereas for the typical supercar (1,436kg with 684hp) the weight it has to propel is 40% higher, at 210kg. It is this weight-to-power calculation that drives the development of the T.50, with every component designed and engineered to achieve the lowest starting weight. This focus and control ensures no retrospective weight-saving measures need to be implemented late in the car’s development.

Weighing just 980kg and powered by a 650hp V12 engine, the T.50 sets a challenging benchmark for rival supercars. To match the T.50’s 663hp/ton, the typical 1,436kg supercar would need an additional 300hp. Of course, the 950hp required to match the T.50 on paper would add cost, complexity, and require larger, heavier components (tyres, drivelines, transmission, brakes, etc.) to handle the extra power.

Weight kills dynamic performance

A heavy car can never deliver the dynamic attributes of a lighter car – even if it has the same power to weight ratio. While it is possible to disguise a heavy car’s dynamic capabilities with complex active suspension and sophisticated electronics, the agility, responsiveness and reward of a lightweight vehicle cannot be matched.

Professor Murray said: “Today, the enjoyment of driving has been lost as so many supercars only come ‘alive’ at the upper-ends of their performance capabilities. Chasing a top speed only adds weight (notably through ever-more powerful engines), so the future of true performance cars lies in shedding weight intelligently.”

Every component counts

With a compact footprint of just 4,380mm (l) x 1,850mm (w), the T.50 is smaller than a Porsche 911 but offers comfortable space for three passengers and luggage. Its fully carbon fibre monocoque and body panels weigh less than 150kg in total. Inside, the three racing-inspired seats are also constructed using carbon fibre. The centrally-positioned driver’s seat weighs less than 7kg, while the passenger seats that flank it to the rear each achieve a weight that is under 3kg.

The T.50 is equipped with a naturally-aspirated V12 powerplant, the world’s highest revving road car engine (12,100rpm), which produces 650bhp. Through exacting standards, innovative engineering and the expertise of Cosworth Powertrain engineers, the weight of the GMA 4-litre unit is less than 180kg. This makes it the lightest road-going V12 ever made and more than 60kg lighter than the BMW S70/2 V12 in the McLaren F1 – while generating more power.

To minimise weight at every stage of development, GMA’s senior design and engineering teams hold a weekly ‘weight watchers’ meeting to review the weight of the car and its components. Monitoring the weight of every part, down to nuts, bolts and washers, the team keeps close checks during every stage of the development process.

This method has seen countless designs, revisions, trials and refinements of components large and small. Highlighting the team’s fanatical mindset around minimising weight is the approach the engineers took to specifying the car’s fixings (nuts, bolts, screws, etc). On many cars, these fixings are generic and far larger than they need to be. For the T.50, the diameter and length of each fixing (around 900 in total) was optimised by calculating the forces to which each would be exposed.

For the Gordon Murray Automotive team, no saving in weight is considered insignificant. For example, the pedal box is 300g lighter than the F1’s and the glazing is 28% thinner than usual while remaining a strong structural component. For the whole team, their lightweighting focus is unwavering, every innovation, test, and revision combines to deliver the purest, lightest, most driver-focused supercar ever.

A customer-focused T.50 launch video is viewable on gordonmurrayautomotive.com

About Gordon Murray Automotive

Gordon Murray Automotive will manufacture exclusive low volume sports cars – the T.50 supercar will be the brand’s halo model. The company forms part of a new corporate organisation for the engineering group, and is positioned as a sister company to Gordon Murray Design. The new business was first announced on November 2017 during an exhibition, named ‘One Formula’, which celebrated Murray’s 50 years of car design.

About Gordon Murray Design

Gordon Murray Design is a visionary design and engineering company headquartered in Surrey, UK. Established in 2007, its focus is on developing innovative and disruptive manufacturing technologies trademarked iStream®. The company has built a global reputation as one of the finest automotive design and engineering teams in the world.

The company’s unique approach and truly creative thinking enables Gordon Murray Design to deliver complete car programmes in a highly efficient and innovative way from concept and design, through to prototype and development for production.

About Professor Gordon Murray, CBE

Having spent 20 years as Technical Director to two Formula One teams from 1969-1990 Gordon Murray has a wealth of technical, design and engineering experience. At Brabham he was instrumental in two world championship wins (1981 and 1983) before three consecutive championship wins with McLaren Racing (1988, 1989 and 1990). In 1990 – after 50 Grand Prix wins – Gordon moved away from Formula One to concentrate on establishing a new company for the group, McLaren Cars Limited.

His first project there, the F1 road car, is still regarded as one of the world’s best-engineered cars. A racing version won two world sports car championships and the Le Mans 24-hour race in 1995. McLaren Cars then completed several other successful projects culminating in the Mercedes-Benz SLR McLaren.

Gordon left McLaren in 2005 to set up a Gordon Murray Design Ltd (in 2007), of which he is Chairman. The innovative British company is a world leader in automotive design, and reverses the current industry trend for sub-contracting by having a complete in-house capability for design, prototyping, and development.

In 2017, Gordon Murray Design celebrated the company’s 10-year anniversary along with that of the iStream manufacturing process at a special event, named ‘One Formula’. Gordon also marked the 25th production anniversary of the McLaren F1 road car, and his 50th year of design and engineering.

In May 2019, Professor Murray was made a Commander of the British Empire (CBE) by the Duke of Cambridge, Prince William, in recognition of his contributions to the motorsport and automotive sectors over the past 50 years.

You must be logged in to post a comment.