This spring saw the first of the series-produced new Volvo FH trucks roll out of the factory gates for delivery to customers throughout Europe. But just how is an ultra-modern truck built, how do advanced electronics and other hardware turn into a single smoothly functioning entity and how can top quality be guaranteed ?

Join Volvo Trucks on a trip from initial idea to finished truck….

The new Volvo FH has been dubbed the “next-generation truck”. Jonas Nordqvist, product feature and profitability manager in the strategic planning department at Volvo Trucks, talks about what this actually means.

“One might say that an ultra-modern truck must meet all the conditions of a complex equation. It must satisfy both customer requirements and society’s demands and succeed in combining modern technology with properties such as quality, driver comfort, environmental efficiency and safety,” explains Jonas Nordqvist.

Work on the development of a modern truck starts long before production is even relevant. The hunt for the highest possible quality characterises every aspect of the process from start to finish. Careful analysis of customers, society and the competition indicates which demands a new truck model will have to meet. The market is also scanned to identify which technological innovations can be integrated into the new product. This data then forms the basis for a detailed requirement specification that governs how a modern truck should be built.

Production – a crucial factor

Once the requirement specification has been set, it is time for the next challenge: to transform ideas into reality. In order to succeed here it is necessary to implement cross-functional working methods where everyone – from design to construction and production – works together from Day one.

“One of the most important parameters in the development of an entirely new truck is that it should actually be able to be built. That may sound rather obvious, but it is vital that the production process is ergonomic, efficient and repeatable. Ultimately it’s all about being able to guarantee a high-quality product,” says Jonas Nordqvist.

The fact that series production of the new Volvo FH is in full swing, and the fact that the first trucks are now on their way to their customers, not only marks the start of something new, it also marks the end of a long development journey. For the European Volvo plants in Sweden, Russia and Belgium the focus was on developing the new product in co-operation with the engineers. In parallel they also produced the documentation for everything that needs to be updated in the plants, as regards both new tooling and new skills.

“This is an entirely new cab; an entirely new truck. There isn’t a single body component that is carried over from the previous model and this imposes demands on both our personnel and on our equipment, since the latter is often product-specific,” relates Hans Elmqvist, project manager for overall production of the new Volvo FH at all the company’s European plants.

New plant investments

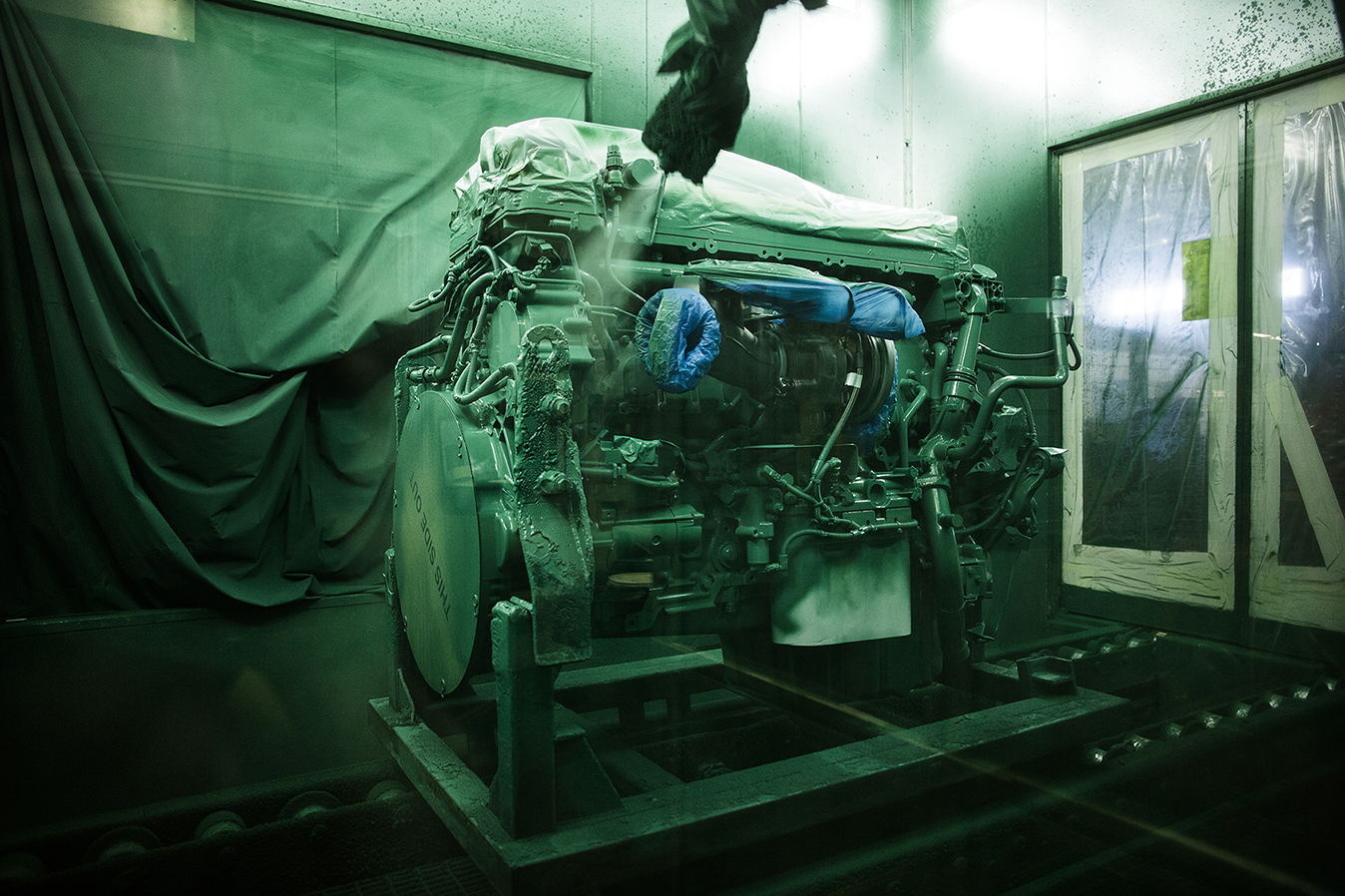

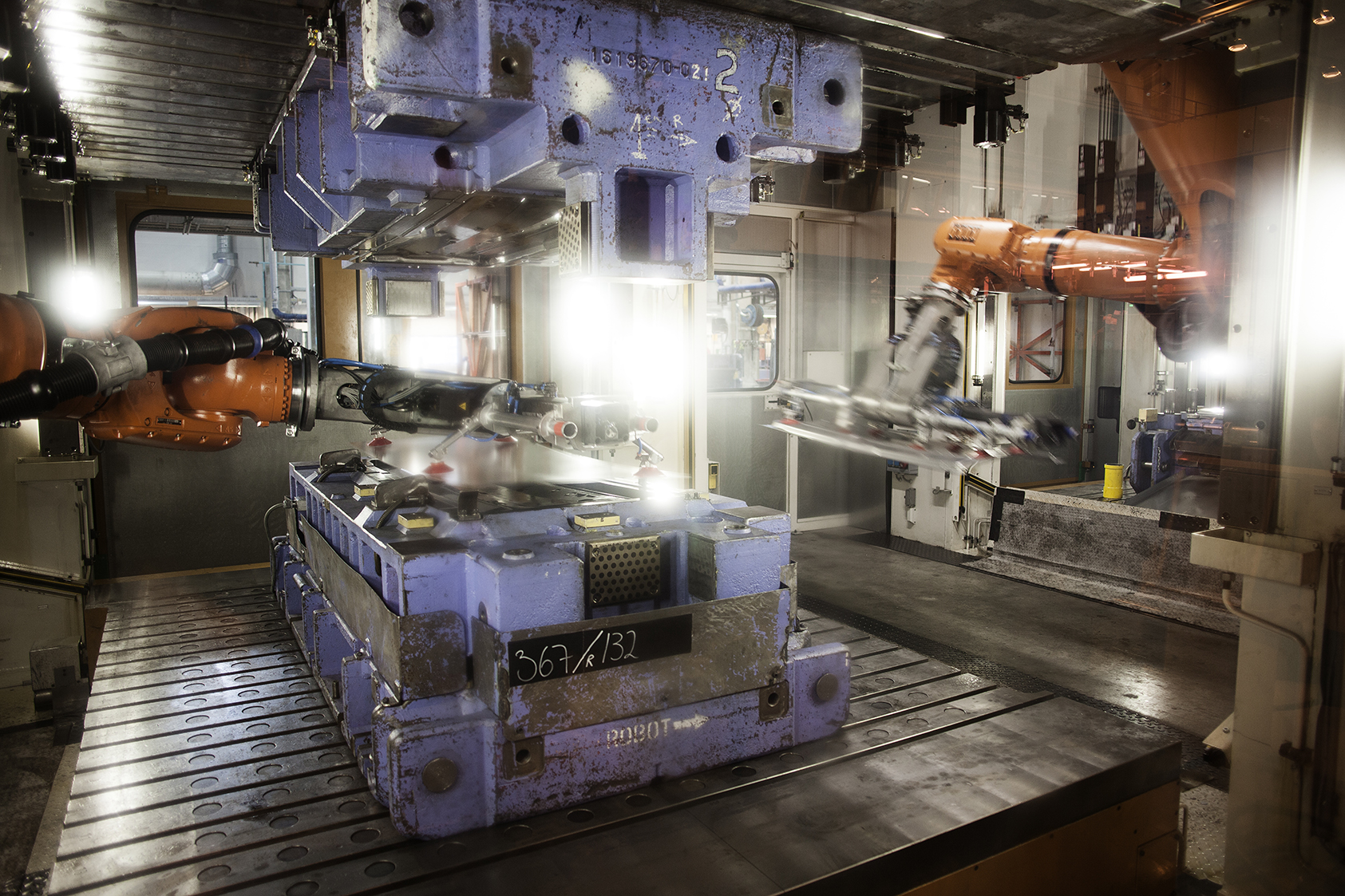

An ultra-modern truck requires ultra-modern production tools. One important investment here is in the new presses, which are used in the production of all the cab parts.

“One thing that is unique in the new Volvo FH is that we press many parts in five steps. The focus here is on geometry assurance – the more times components are pressed, the better the various parts fit together, thus improving cab assembly,” explains Hans Elmqvist.

Another major investment was the purchase of 56 new robots, all of which help improvement production efficiency. Automation also guarantees that each and every truck offers the same high level of quality. One example of this is that all the glass in the truck is now bonded into place. There are two benefits to this: the cab is safer since the windows form part of the cab’s structure and the production process is more efficient and quality-assured than ever before.

Pilot plants for product development

Another important role for the plants was to participate in the development of the new truck. In order to do this without disrupting ongoing production, pilot plants were established in Volvo’s two Swedish factories at Tuve and Umeå. These can be described as miniature replicas of the production plants’ full-scale assembly operations. There the new tools could be tested and method trucks could be built. The aim there was basically to transform theory into practice, to determine the best assembly process and to find out whether it was even possible to build the truck in the sequence and with the tools that the engineers had in mind.

“Just like the human body’s blood circulation system, we go through the entire truck to guarantee that everything works exactly like it should. Advance test production in the pilot plant is an important part of this quality control process,” Hans continues.

The pilot plants also served as a basis for enhancing the competence of the assembly personnel at both local and global level. Over the past few years, key operators from all over the world have worked side by side with truck builders in the pilot plants to learn how the new truck is to be put together. When the time came to move the assembly process to the regular production line in the Swedish plants, the key operators were able to teach their colleagues what to do. The benefits will be the same globally.

“We’re prepared down to the tiniest detail, largely because this is such a complex truck, but one result is that it will be much quicker to roll out a quality-assured production process in the other plants too. The new Volvo FH is tailored for the whole world,” says Hans Elmqvist.

More ergonomic assembly

Having said all this, it is not only the truck itself or the newly-developed tools that are ultra-modern.

The pilot plants also served as an important arena for the development of simpler and more ergonomic routines for the employees. Although the product itself is more complicated, simplifications and smart assembly solutions have made it easier to build the new truck. These include building the chassis upside-down – which promotes a more ergonomic working position with easier to access all the various components – and bonding the windows into place to increase cab strength. Another feature has been to route all the electrical wiring down the right side of the chassis, while air and water lines are located on the left side – all so as to make assembly easier.

“I’d say with absolute conviction that everything that has improved in the production process also benefits the customer. Improved working conditions lead to increased product quality. If something is easy to assemble, it is also easy to do correctly,” summarises Hans Elmqvist.

Did you know that…

… it takes about five days to transform a roll of steel into an ultra-modern truck ?

… the cab passes through about 350 pairs of hands before it is fully assembled ?

… 3.8 litres of paint are needed to paint a Volvo FH topcoat ?

… the press tools weigh between 25 and 30 tonnes each ?

… 2790 screws are used in the building of an ultra-modern truck ?

… the new Volvo FH weighs between 7,500 and 12,500 kg (depending on specification) ?

You must be logged in to post a comment.